Explore the unique characteristics, applications, and future prospects of hysteresis motors in our comprehensive guide.

Introduction to Hysteresis Motors

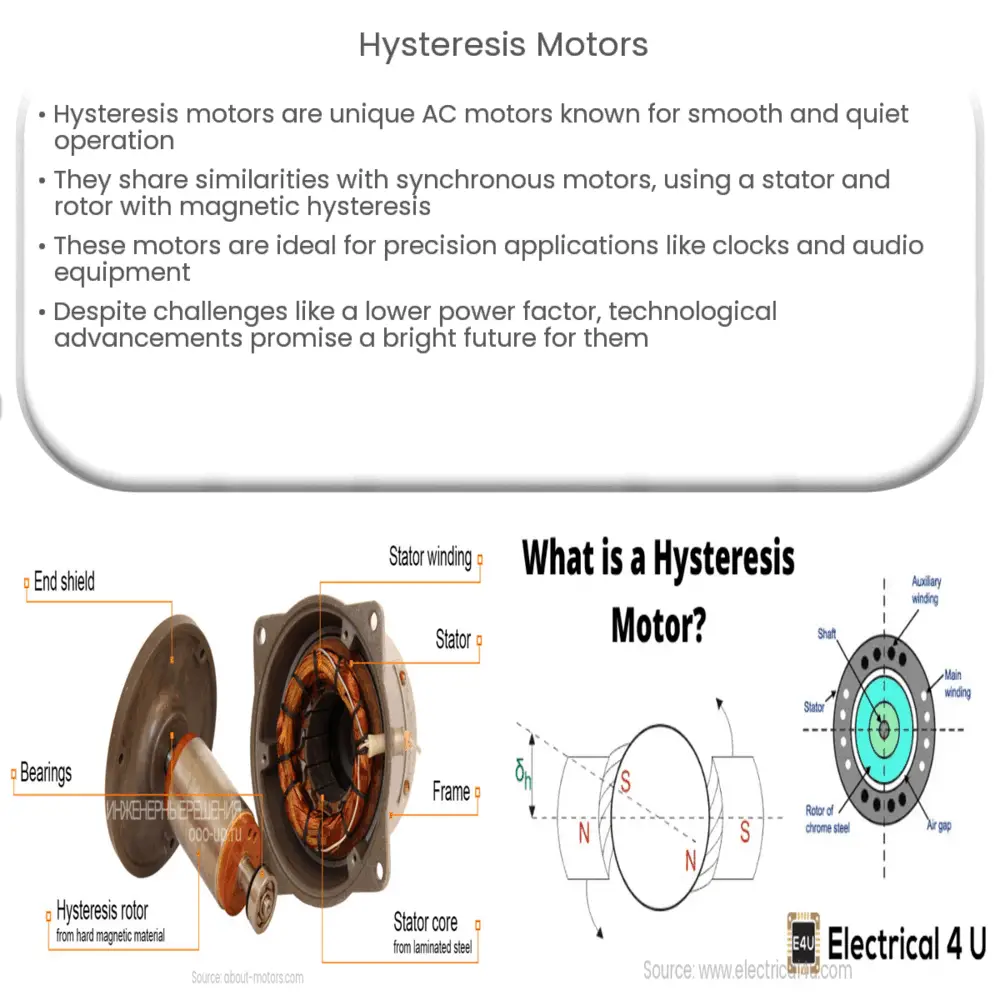

A hysteresis motor is a unique type of AC motor, renowned for its exceptional characteristics, which make it stand out in the electric motor landscape. This motor type belongs to the synchronous motor family, though with some unique attributes that set it apart.

Construction and Operation Principles

Structurally, hysteresis motors share many similarities with conventional synchronous motors. They comprise two primary components: a stator and a rotor. The stator consists of windings that create an alternating magnetic field when energized with AC power, while the rotor is generally crafted from a material with high magnetic hysteresis, typically Cobalt-steel alloy.

The operating principle of the hysteresis motor revolves around the concept of ‘magnetic hysteresis’, hence its name. When the stator’s magnetic field is activated, it induces a lagging magnetic field in the rotor, causing it to turn and, thus, producing rotational motion.

Unique Attributes of Hysteresis Motors

-

Smooth Operation: Due to the non-contact nature of the torque production process, hysteresis motors operate extremely smoothly and quietly. The lack of torque pulsations significantly reduces vibrations, contributing to their quiet operation.

-

High Speed Accuracy and Control: Hysteresis motors exhibit a constant synchronous speed, irrespective of the load. This high-speed accuracy and control make them particularly suitable for precision applications, such as in clocks, record players, and tape drives.

-

Low Power Factor: An important consideration when working with hysteresis motors is their lower power factor. This is due to the lagging magnetic field in the rotor, which can result in increased reactive power and potentially inefficient operation.

Hysteresis Motors in Applications

The unique benefits of hysteresis motors make them a sought-after choice for specific applications. For instance, they are ideal for use in equipment demanding low noise and high precision. Some of these applications include audio equipment, measuring instruments, and precise mechanical devices.

The Challenges and Opportunities

While the advantages of hysteresis motors are compelling, it’s important to note that they also present certain challenges. For one, they tend to be more costly than other motor types due to their specialized rotor materials and construction. Additionally, their low power factor may lead to inefficient energy usage in certain scenarios. Despite these challenges, advancements in material science and engineering present exciting opportunities for improving the efficiency and cost-effectiveness of hysteresis motors.

Advancements and Developments in Hysteresis Motors

Recent advancements in materials science and design techniques promise to further enhance the performance and efficiency of hysteresis motors. The development of novel high-coercivity materials, for instance, could lead to more efficient rotors that contribute to a higher power factor. Additionally, advancements in winding design and construction could result in more effective induction of the magnetic field, further improving efficiency and performance.

Environmental Impact and Energy Efficiency

In today’s energy-conscious world, the focus on sustainable and efficient electric motor operation has never been greater. Hysteresis motors, with their potential for high efficiency and silent operation, play a significant role in this landscape. Their inherent advantages make them suitable for applications where energy conservation and low noise are essential. However, ongoing research is necessary to further improve their energy efficiency and mitigate the challenges associated with their low power factor.

Future of Hysteresis Motors

The future of hysteresis motors is quite promising. With increasing interest in precision applications and the growing demand for quiet electric motors in consumer electronics and medical devices, the adoption of hysteresis motors is expected to rise. Additionally, continued research and technological advancements could pave the way for their increased application in a wider variety of fields.

Conclusion

In conclusion, hysteresis motors offer a unique set of advantages that set them apart in the realm of AC motors. Their smooth and quiet operation, combined with high-speed accuracy, make them ideal for precision applications. Despite certain challenges such as a lower power factor and higher costs, ongoing developments in materials science and design methodologies suggest a bright future for hysteresis motors. As technological advancements continue to push the boundaries of what’s possible, these specialized motors are poised to play an increasingly important role in a wide variety of applications, marking an exciting era for hysteresis motors in the field of electric motor technology.