Hydraulic load cells convert mechanical force into hydraulic pressure for accurate measurement in various industries and applications.

Introduction to Hydraulic Load Cells: Principles and Applications

What is a Hydraulic Load Cell?

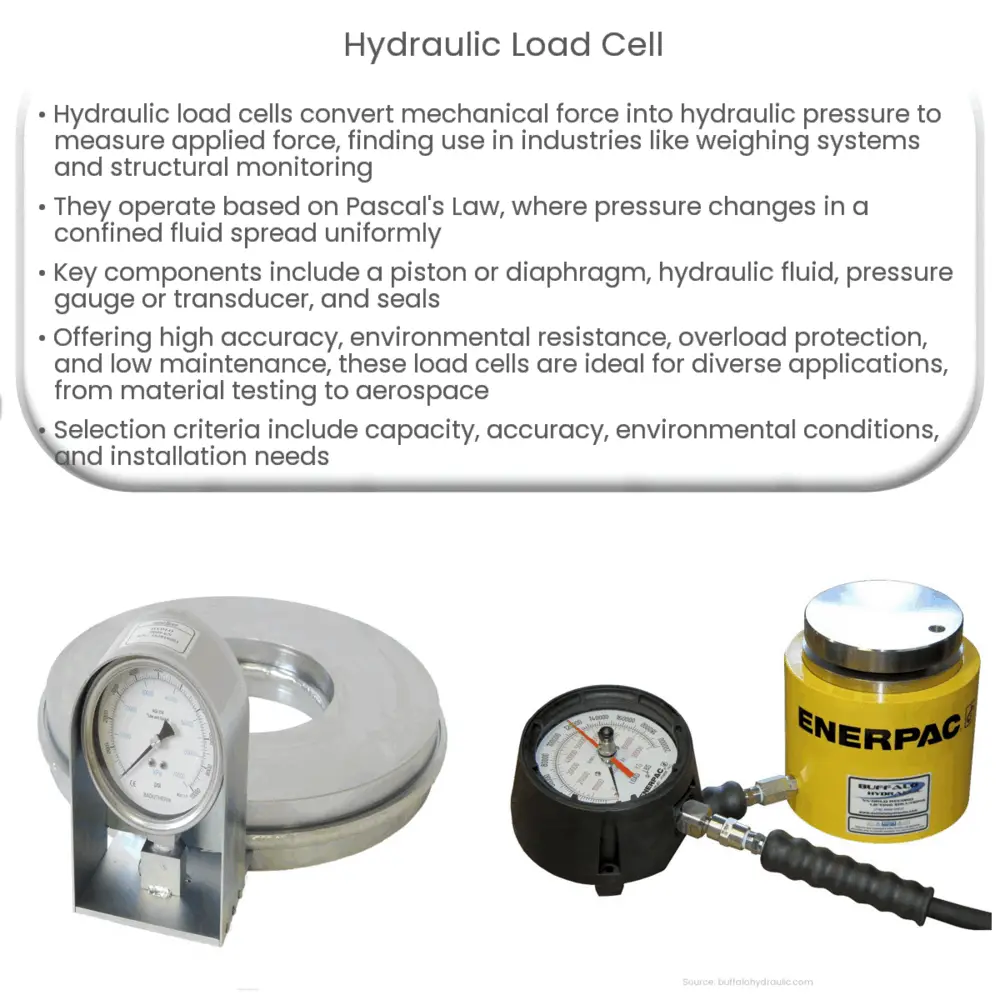

A hydraulic load cell is a type of force transducer that converts mechanical force into hydraulic pressure, which can then be measured to determine the applied force. It is a crucial component in various industrial and commercial applications, ranging from weighing systems to structural monitoring. Hydraulic load cells have become increasingly popular in recent years, primarily due to their high accuracy, durability, and resistance to environmental factors such as temperature and humidity.

Working Principle of Hydraulic Load Cells

Hydraulic load cells operate based on Pascal’s Law, which states that any change in pressure applied to a confined fluid will be transmitted uniformly in all directions throughout the fluid. In the case of a hydraulic load cell, the mechanical force applied to the device is converted into hydraulic pressure through a piston or diaphragm arrangement. This pressure is then transmitted through the hydraulic fluid to a pressure gauge or transducer, where it is measured and converted into an electrical signal proportional to the applied force.

Key Components of a Hydraulic Load Cell

There are several essential components in a hydraulic load cell, including:

- Piston or Diaphragm: This component is responsible for converting the mechanical force into hydraulic pressure. The force applied to the piston or diaphragm compresses the hydraulic fluid, resulting in a change in pressure.

- Hydraulic Fluid: The fluid, often oil or another incompressible liquid, is used to transmit the pressure generated by the applied force. The hydraulic fluid must be chosen carefully to ensure consistent performance and resistance to temperature fluctuations.

- Pressure Gauge or Transducer: This component measures the hydraulic pressure and converts it into an electrical signal proportional to the applied force. Pressure gauges are typically used for local readout, while pressure transducers are used for remote monitoring and data acquisition.

- Seals and Gaskets: To prevent leakage of hydraulic fluid and maintain accurate pressure readings, seals and gaskets are employed at various points within the load cell assembly. These components must be durable and resistant to environmental factors to ensure the long-term performance of the load cell.

Advantages of Hydraulic Load Cells

Hydraulic load cells offer several advantages over other types of load cells, such as strain gauge or capacitive load cells. Some of the key benefits include:

- High Accuracy: Hydraulic load cells are known for their exceptional accuracy, often providing measurement accuracies of 0.1% or better.

- Environmental Resistance: These load cells are inherently resistant to temperature fluctuations, humidity, and other environmental factors, making them suitable for use in harsh industrial settings.

- Overload Protection: Hydraulic load cells can often tolerate overloads of up to 1000% or more without permanent damage, providing a significant safety margin in applications where sudden load increases may occur.

- Low Maintenance: Due to their robust design and lack of sensitive electronic components, hydraulic load cells require minimal maintenance and are less susceptible to damage from physical shock or vibration.

Applications of Hydraulic Load Cells

Hydraulic load cells are utilized in a wide range of industries and applications, including:

- Weighing Systems: Hydraulic load cells are commonly used in truck scales, railway scales, and other large-capacity weighing systems, where high accuracy and durability are essential.

- Structural Monitoring: These load cells are employed in monitoring the forces and stresses in structures such as bridges, dams, and buildings, enabling early detection of potential structural issues and ensuring safety.

- Material Testing: Hydraulic load cells are often used in material testing applications, where precise force measurements are required to evaluate the mechanical properties of materials and components.

- Aerospace and Automotive: In these industries, hydraulic load cells are used to measure forces during various testing processes, such as engine thrust testing or crash impact testing.

Selection Criteria for Hydraulic Load Cells

When choosing a hydraulic load cell, several factors should be considered to ensure optimal performance in a specific application:

- Capacity: The load cell’s capacity should be selected based on the maximum force expected in the application. A suitable safety margin should also be considered to account for potential overloads.

- Accuracy: The required accuracy of the load cell depends on the specific application and desired level of measurement precision. High-accuracy load cells may be necessary for certain applications such as material testing or structural monitoring.

- Environmental Conditions: The load cell should be selected based on the environmental conditions in which it will be used, including temperature and humidity ranges, as well as exposure to dust, moisture, or corrosive substances.

- Mounting and Installation: The load cell should be compatible with the desired mounting configuration and installation requirements, such as space constraints, load orientation, and required hardware.

Conclusion

Hydraulic load cells offer numerous advantages over other types of load cells, including high accuracy, resistance to environmental factors, overload protection, and low maintenance. Their versatility and durability make them suitable for a wide range of applications, such as weighing systems, structural monitoring, material testing, and aerospace and automotive testing. By carefully considering the selection criteria, users can ensure that they choose the most appropriate hydraulic load cell for their specific needs, resulting in reliable and accurate force measurements in various settings.