Consider application requirements, conductivity range, temperature, cost, mechanical and thermal properties, processing, and corrosion resistance.

Selecting Materials with Appropriate Electrical Conductivity

Selecting materials with suitable electrical conductivity is essential for various applications, from electronics to energy transmission. It involves understanding the specific requirements of the application and evaluating materials based on their conductivity, cost, and other properties. The following are crucial factors to consider:

1. Application Requirements

Before choosing a material, it’s vital to understand the specific needs of the application. For instance, electrical connectors require high conductivity, while insulators must have low conductivity. Superconductors, on the other hand, must exhibit zero electrical resistance.

2. Conductivity Range

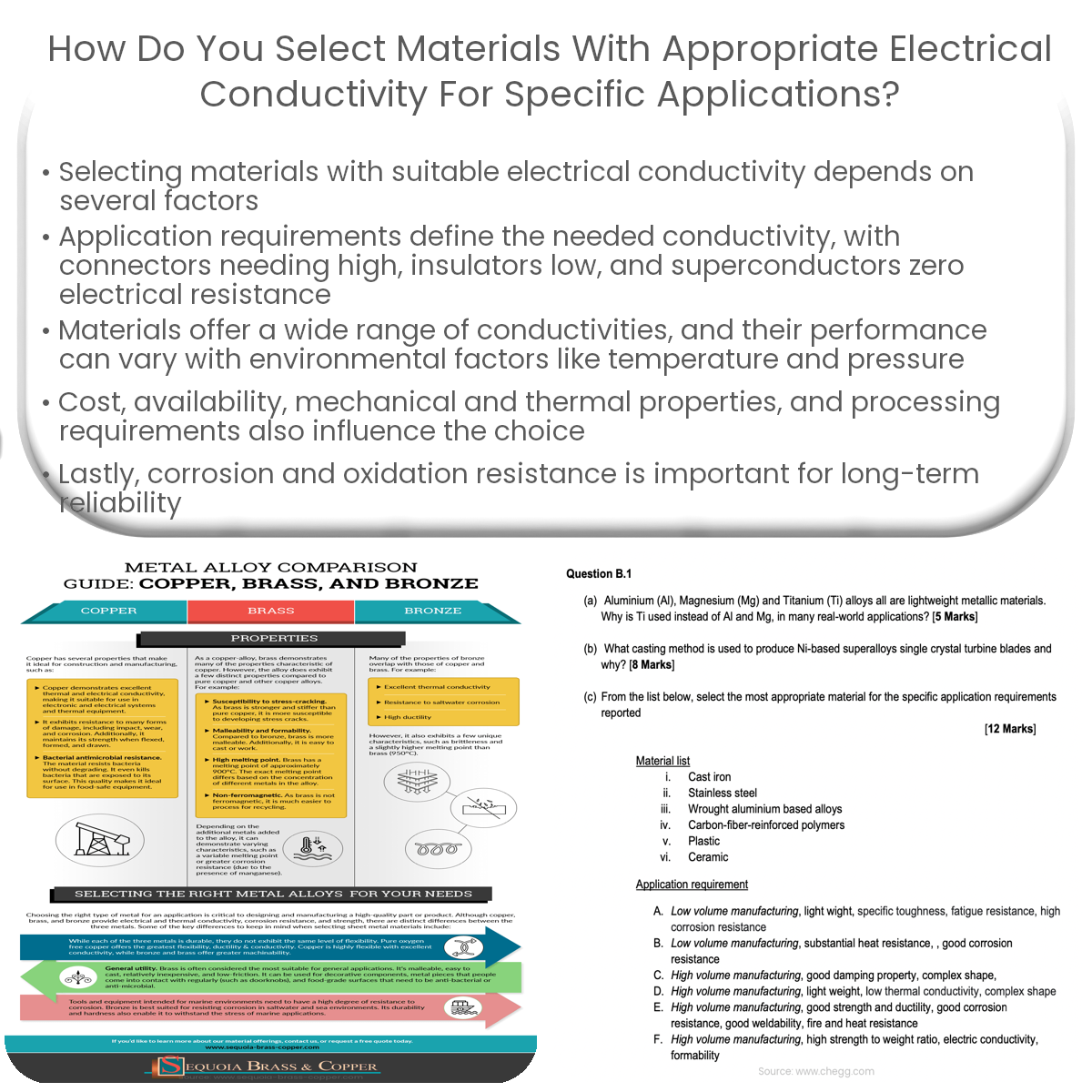

Materials exhibit a wide range of electrical conductivities. Metals like copper and silver offer high conductivity, while ceramics and polymers generally have low conductivity. Understanding the required conductivity range for your application will help narrow down the choices.

3. Temperature and Environmental Factors

The electrical conductivity of a material can change with temperature, pressure, and other environmental factors. Some materials might perform well under specific conditions but fail under others. Ensure that the chosen material can maintain its conductivity under the operating conditions of your application.

4. Cost and Availability

Highly conductive materials can be expensive and scarce. When selecting a material, consider its cost and availability. There might be alternatives that provide adequate conductivity at a lower price or are more readily available.

5. Mechanical and Thermal Properties

Material selection should also consider mechanical and thermal properties, such as strength, ductility, and thermal conductivity. These properties can affect the performance and reliability of the final product.

6. Processing and Manufacturing

Some materials may require specific processing or manufacturing techniques, which can impact the overall cost and feasibility of using them. Consider the compatibility of the material with existing manufacturing processes or the need for new techniques.

7. Corrosion and Oxidation Resistance

Materials with high electrical conductivity might be susceptible to corrosion or oxidation, which can reduce their performance over time. Select materials that can withstand these effects to ensure long-term reliability.

By considering these factors and consulting with material experts, you can select the appropriate material with the required electrical conductivity for your specific application, ensuring optimal performance and longevity.