DC motors work by converting electrical energy into mechanical energy through the interaction of magnetic fields produced by the stator and rotor.

Understanding DC Motors

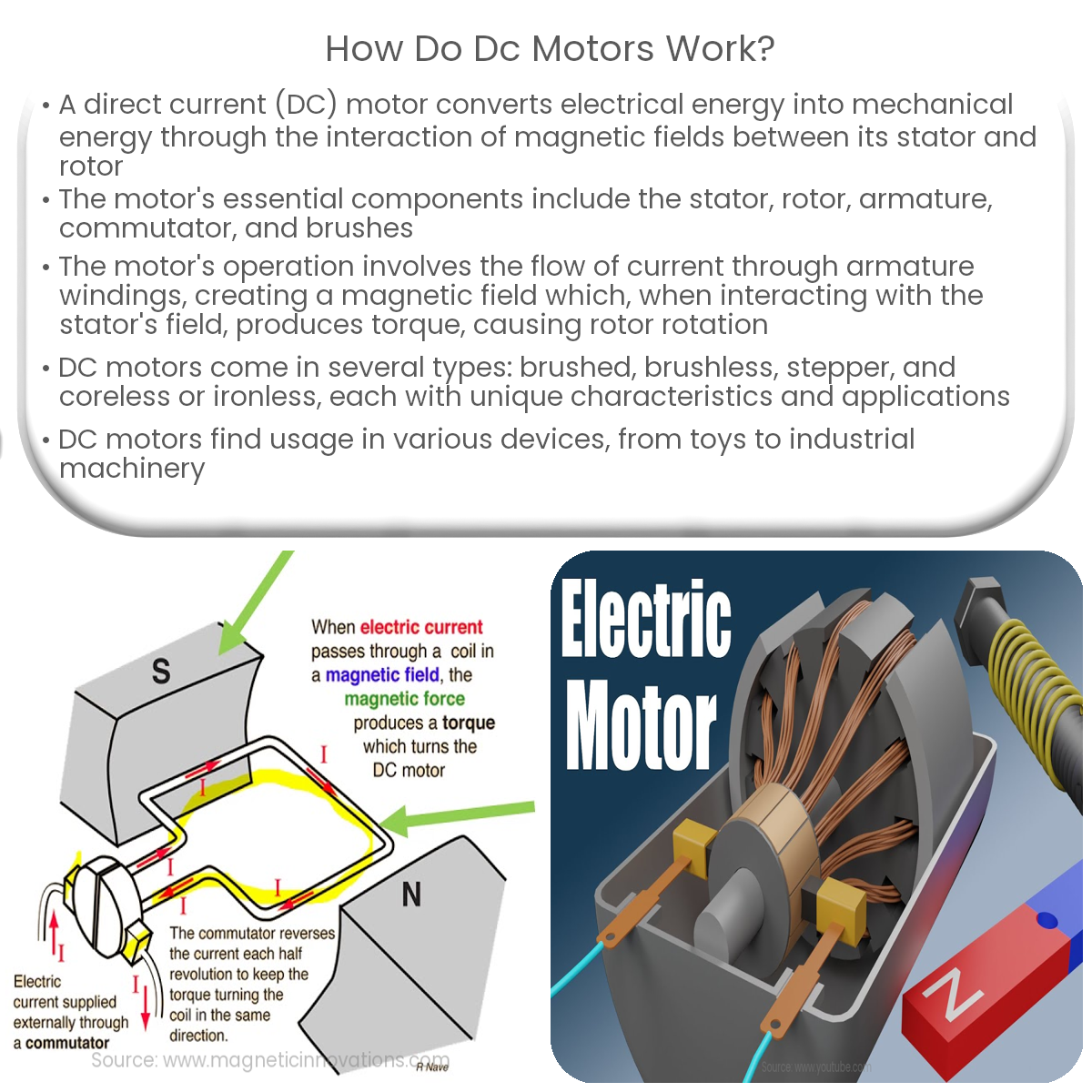

A direct current (DC) motor is a type of electric motor that converts direct current electrical energy into mechanical energy. The basic principle behind its operation is the interaction between the magnetic fields generated by the stator and the rotor, resulting in a rotational force.

Components of a DC Motor

DC motors consist of several key components, including:

- Stator: The stationary part of the motor that houses the permanent magnets or the electromagnets, which produce the magnetic field.

- Rotor: The rotating part of the motor that contains the armature, windings, and the commutator.

- Armature: The winding coils placed on the rotor, which carry current and produce torque due to the interaction with the stator’s magnetic field.

- Commutator: A rotating switch that reverses the current direction in the armature windings, maintaining continuous rotation.

- Brushes: These components maintain electrical contact with the commutator as it rotates.

Working Principle of DC Motors

The operation of a DC motor is based on the interaction of magnetic fields, which create a force that causes the rotor to rotate. When a DC voltage is applied to the motor, current flows through the armature windings, generating a magnetic field around them. This magnetic field interacts with the magnetic field produced by the stator, resulting in a force called torque that causes the rotor to rotate.

The commutator ensures continuous rotation by periodically reversing the direction of the current in the armature windings. As the rotor turns, the brushes maintain contact with the commutator, allowing the current to flow through the windings. The commutator’s segments switch the current’s direction in the windings, ensuring that the torque is always in the same direction, resulting in smooth rotation.

Types of DC Motors

There are several types of DC motors, each with its own characteristics and applications:

- Brushed DC motors: These motors use brushes and a commutator to switch the current in the windings, providing a simple and cost-effective solution for many applications.

- Brushless DC motors: These motors use electronic commutation instead of brushes, providing higher efficiency, longer life, and reduced maintenance requirements.

- Stepper motors: These motors are a type of brushless DC motor that can be controlled to move in precise steps, making them suitable for positioning applications.

- Coreless or ironless DC motors: These motors have a rotor without iron, reducing the cogging effect and providing smooth operation at low speeds.

DC motors are widely used in various applications, from small devices such as toys and electric toothbrushes to larger systems like electric vehicles and industrial machinery.