Explore the world of gas-bearing gyroscopes, their working principle, types, applications, pros and cons, and their future prospects.

Introduction to Gas-bearing Gyroscopes

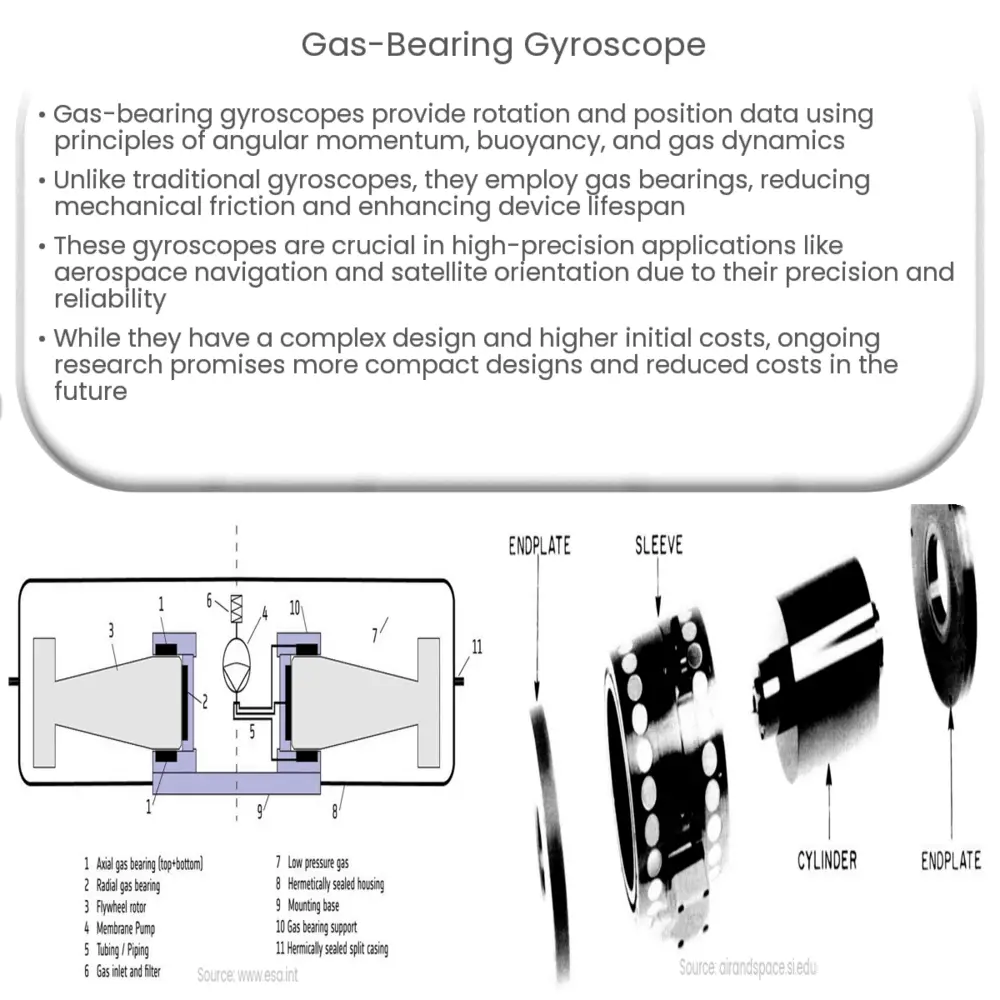

A gas-bearing gyroscope is a sophisticated device designed to provide rotation and position information. It incorporates the principles of angular momentum, buoyancy, and gas dynamics. Although it is similar to other types of gyroscopes, the gas-bearing gyroscope has unique characteristics that distinguish it from its counterparts.

In a traditional gyroscope, mechanical bearings are used to maintain the rotor’s equilibrium and position. Conversely, the gas-bearing gyroscope utilizes gas bearings, creating a non-contact method for maintaining rotor equilibrium. This particular method substantially reduces mechanical friction, which can potentially increase the lifespan and reliability of the device.

Working Mechanism of a Gas-bearing Gyroscope

The operation of a gas-bearing gyroscope is based on the principle of gas dynamics. A pressurized gas, typically air or helium, is directed towards the rotor’s surface. This pressurized gas forms a thin film between the rotor and its housing, levitating the rotor and enabling it to spin freely without any physical contact with the structure. Thus, the gas-bearing gyroscope achieves a highly accurate and reliable rotation rate measurement.

Types of Gas Bearings in Gyroscopes

- Externally Pressurized Gas Bearings: In this type, gas is supplied under pressure from an external source to the bearing. This setup can control the gas film thickness and ensure a steady supply of gas, leading to a reliable and robust operation.

- Self-acting Gas Bearings: These bearings generate their own pressure due to the rotor’s motion. They require no external pressure source, making them simpler and more compact. However, they might not provide as much stability as externally pressurized bearings.

The choice between externally pressurized and self-acting gas bearings depends on the specific requirements of the application, such as size, weight, stability, and overall system complexity.

Applications of Gas-bearing Gyroscopes

Gas-bearing gyroscopes are commonly used in high-precision applications that demand minimal drift and high reliability. This includes areas like aerospace navigation, satellite orientation, and deep-sea exploration, where precision and reliability are critical. In these fields, the gas-bearing gyroscope’s capacity to offer long operational life, high precision, and low drift rate makes it an invaluable tool.

Continued in the next section…

Advantages and Disadvantages of Gas-bearing Gyroscopes

Like all technologies, gas-bearing gyroscopes have both advantages and disadvantages that need to be considered when selecting them for use in specific applications.

Advantages

- Reduced Friction: Since the rotor does not make physical contact with the bearings, friction is minimized. This results in increased lifespan and operational efficiency.

- High Precision: Due to reduced mechanical friction, gas-bearing gyroscopes are capable of providing highly precise rotational data.

- Long Operational Life: Lower friction and wear lead to extended operational life, making gas-bearing gyroscopes a preferred choice for long-term applications.

Disadvantages

- Complex Design: The design and implementation of gas bearings can be complex, requiring expertise and precision engineering.

- High Initial Cost: The cost of producing gas-bearing gyroscopes is usually higher compared to other types due to the complexity of their design and construction.

Future of Gas-Bearing Gyroscopes

The future of gas-bearing gyroscopes seems promising, as ongoing research is targeting the downsides and working towards enhancements. As the trend of miniaturization continues, gas-bearing gyroscopes may find their way into even more compact and precise applications. Moreover, as technology advances, the costs associated with these devices are expected to decrease, making them more accessible for a broader range of applications.

Conclusion

In conclusion, gas-bearing gyroscopes serve as a pivotal tool in applications that demand high precision and reliability. Despite their complex design and initial cost, their advantages in terms of reduced friction, increased lifespan, and high precision make them a valuable asset in the fields of aerospace navigation, satellite orientation, and deep-sea exploration. With ongoing research and development, these gyroscopes are set to play an even more significant role in the future of navigation and positioning systems.