Force-sensitive resistors (FSRs) are thin, flexible sensors that detect force or pressure by changing their resistance values.

Force-Sensitive Resistor (FSR): An Overview

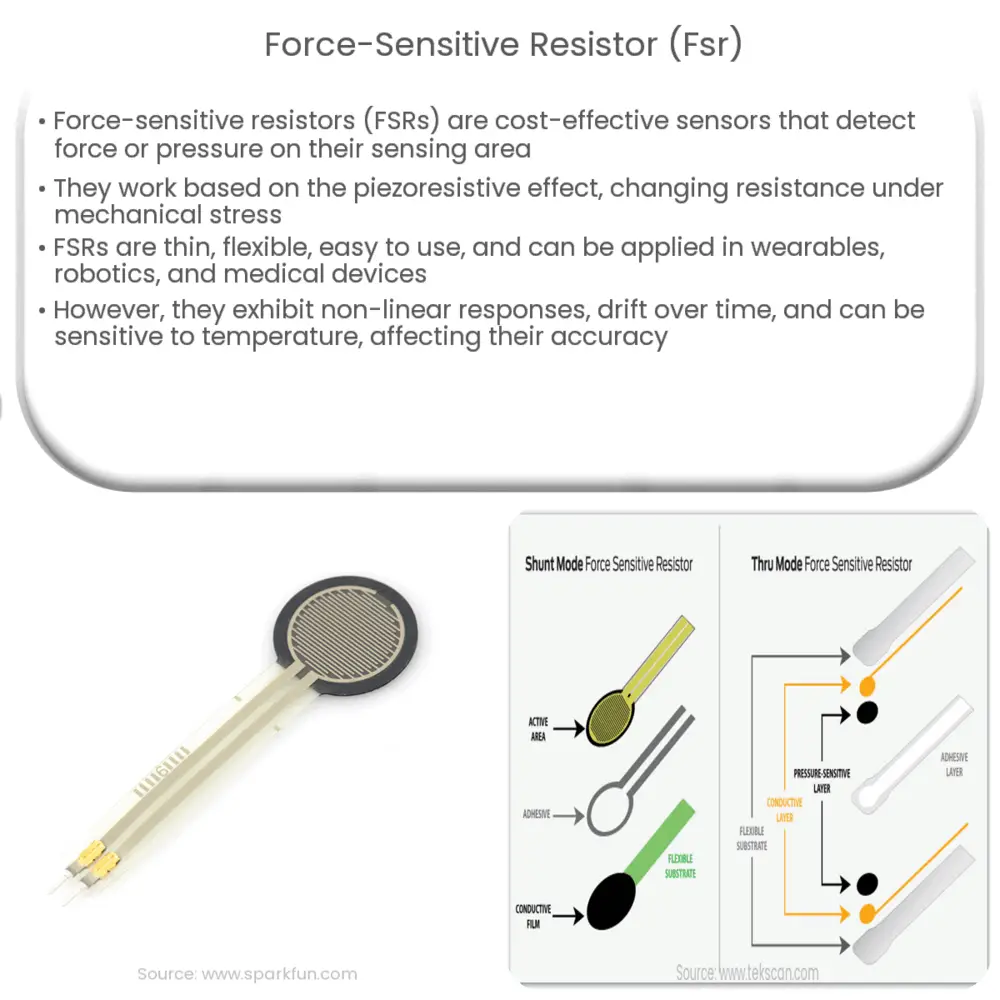

Force-sensitive resistors, commonly referred to as FSRs, are a versatile and cost-effective sensor technology used in a wide range of applications. They are particularly popular for their ability to detect the presence and magnitude of force or pressure applied to their sensing area. This article will provide an in-depth look at FSR technology, its working principles, and the advantages and disadvantages of using FSRs in various applications.

What is a Force-Sensitive Resistor (FSR)?

A force-sensitive resistor is a type of variable resistor whose resistance value changes in response to the force or pressure applied to its sensing surface. Typically made from a thin, flexible substrate, FSRs are composed of conductive and resistive layers that are separated by a layer of spacer dots. When pressure is applied, these spacer dots compress, allowing the conductive layer to make contact with the resistive layer, resulting in a change in resistance that can be measured and interpreted by an external circuit.

How Do FSRs Work?

The working principle of an FSR is based on the piezoresistive effect, which is the change in electrical resistance that occurs in certain materials when subjected to mechanical stress. The FSR consists of two primary layers: the conductive layer, which contains conductive particles such as silver or carbon, and the resistive layer, which contains particles of a resistive material like a polymer. When force is applied to the sensor, the conductive particles move closer together, creating more pathways for electrical current to flow, thus decreasing the overall resistance of the sensor.

The change in resistance can be measured using a simple voltage divider circuit, where the FSR is connected in series with a known resistor. As the resistance of the FSR changes, the voltage across it also changes, providing an electrical signal that can be used to determine the applied force. This signal can then be fed into a microcontroller or other processing unit for further analysis or control purposes.

Advantages of Force-Sensitive Resistors

- Cost-effective: FSRs are relatively inexpensive compared to other force-sensing technologies, making them an attractive option for budget-sensitive projects.

- Thin and flexible: The thin form factor and flexibility of FSRs allow for easy integration into a variety of applications, such as wearable devices and robotics.

- Simple to use: FSRs require minimal additional components to function, simplifying their implementation in projects.

- Wide range of force sensitivity: FSRs can be designed to sense a broad range of force values, making them suitable for various applications.

Disadvantages of Force-Sensitive Resistors

- Non-linear response: The relationship between force and resistance in FSRs is not linear, which can complicate signal processing and calibration efforts.

- Drift over time: FSRs may exhibit drift in their resistance values over time, affecting the accuracy and consistency of measurements.

- Sensitivity to temperature: The resistance of FSRs can be influenced by temperature changes, leading to potential inaccuracies in force measurements.

- Lower precision: Compared to other force-sensing technologies, FSRs generally have lower precision and accuracy, making them less suitable for applications requiring high precision.

Common Applications of Force-Sensitive Resistors

FSRs find use in a diverse array of applications across various industries. Some common examples include:

- Human-machine interfaces: FSRs can be used to create pressure-sensitive buttons, touchpads, or other input devices for controlling electronic systems.

- Wearable technology: The flexibility and thin form factor of FSRs make them ideal for integration into wearable devices, such as smart shoes and fitness trackers, to measure force and pressure in real-time.

- Robotics: FSRs can be employed in robotic systems for detecting contact forces, enabling delicate manipulation tasks and safe human-robot interactions.

- Automotive: FSRs can be used to monitor seat occupancy, steering wheel grip, or brake pedal pressure in vehicles for enhanced safety and comfort.

- Medical devices: FSRs are utilized in various medical devices, such as blood pressure monitors and respiratory equipment, to measure force and pressure accurately and noninvasively.

Conclusion

Force-sensitive resistors are a versatile and cost-effective sensor technology with a wide range of applications. Their thin, flexible form factor and simple operation make them an attractive option for many projects. However, their non-linear response, drift over time, and sensitivity to temperature must be considered when selecting an FSR for a specific application. With proper calibration and signal processing techniques, FSRs can be a valuable addition to numerous applications, from wearable technology and robotics to automotive and medical devices.