Explore the functionality, benefits, applications, and future prospects of Electrostatic Fluidized Bed Coating Systems in our detailed guide.

Introduction to Electrostatic Fluidized Bed Coating Systems

Technological advancement has touched every industry, including manufacturing and production sectors, which continually seek methods to increase efficiency and quality. One technology that has become critical in these areas is the Electrostatic Fluidized Bed Coating Systems.

Essentially, these systems use the principles of electrostatics and fluidization to ensure high-quality coating of surfaces, mainly in the powder coating industry. This method is particularly appreciated due to its cost-effectiveness, uniform coating thickness, and high transfer efficiency.

Working Principle of Electrostatic Fluidized Bed Coating Systems

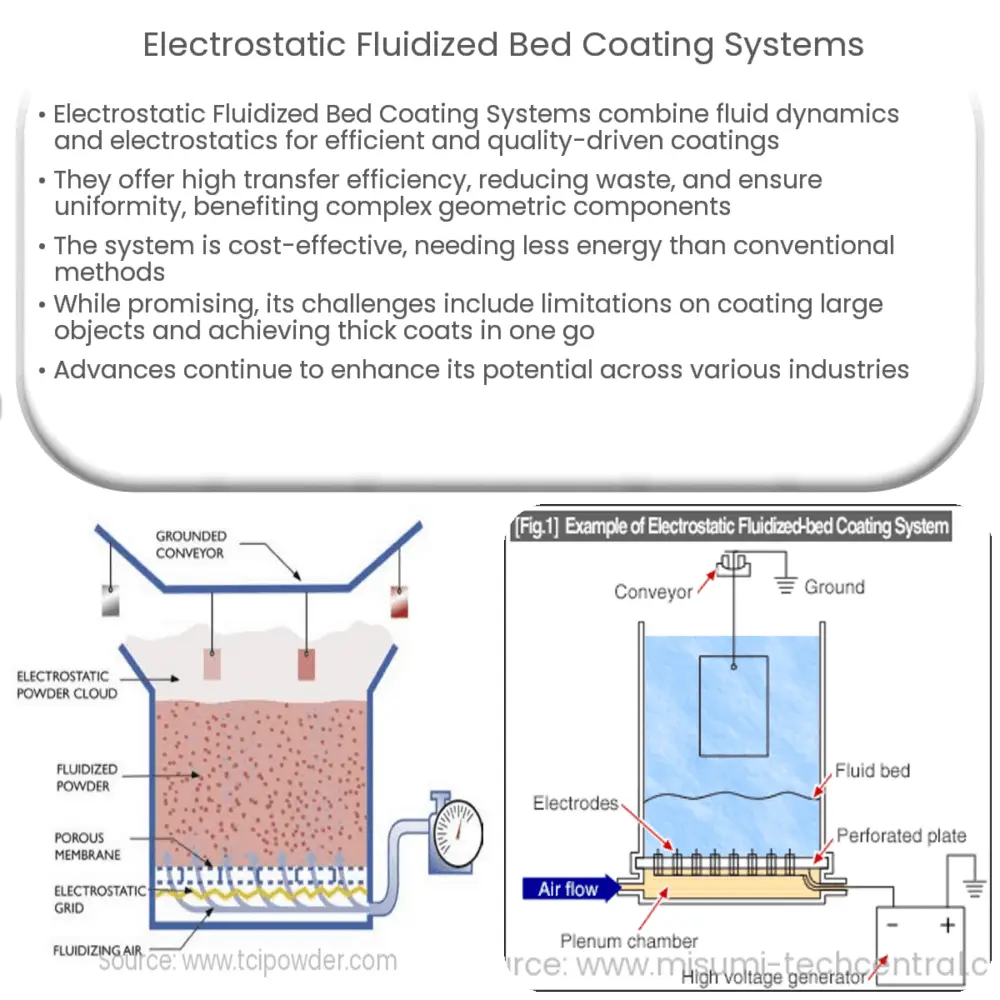

In an Electrostatic Fluidized Bed Coating System, the coating process begins by submerging the part to be coated into a fluidized bed of fine powder. The bed is fluidized by forcing a stream of air from the bottom of the tank, causing the powdered particles to exhibit fluid-like behavior. The part acts as one electrode, while the powder particles become charged as they make contact with an electrode at the bottom of the tank.

As a result, these charged particles adhere to the surface of the part due to the electrostatic attraction, providing a uniform, high-quality coating. The part is then heated in a curing oven, allowing the coating to melt and form a smooth and continuous layer.

Advantages of Electrostatic Fluidized Bed Coating

-

One of the significant advantages of using this system is its high transfer efficiency. Unlike traditional coating methods where a considerable amount of material is lost during application, this method ensures most of the charged particles adhere to the surface, reducing waste.

-

The second advantage is the uniformity of the coating. The electrostatic attraction ensures that the coating adheres evenly to the surface, regardless of its shape or complexity. This feature is particularly beneficial for complex geometric components.

-

The third notable advantage is its cost-effectiveness. Not only does the system reduce material waste, but it also requires less energy to operate compared to conventional systems, making it a more economical choice in the long run.

Thus, the Electrostatic Fluidized Bed Coating System combines the principles of fluid dynamics and electrostatics to deliver a highly efficient, cost-effective, and quality-driven solution for the coating industry.

Applications of Electrostatic Fluidized Bed Coating Systems

Electrostatic fluidized bed coating systems find widespread use in various industries. Here are a few noteworthy applications:

-

Automotive industry: Given its high transfer efficiency and uniform coating abilities, this method is commonly employed in the automotive sector for coating various parts including wheels, brake components, and suspension parts.

-

Electronics: In the electronics industry, components often require a protective or insulating coating. The high precision and uniformity of electrostatic fluidized bed coating systems make them ideal for this purpose.

-

Appliances: Many household appliances have coated surfaces for both aesthetics and functionality. Electrostatic fluidized bed systems provide a high-quality, durable finish that enhances the product’s overall appeal.

Challenges and Future Prospects

Despite its many advantages, the Electrostatic Fluidized Bed Coating System is not without its challenges. For instance, it may not be suitable for coating very large objects due to the limitations of the fluidized bed size. Additionally, while it provides uniform coating, achieving a thick coat in a single application can be challenging.

However, continual advancements are being made in this technology to overcome these hurdles. Developments in the fluidization process, charging methods, and curing processes promise to further enhance the performance and scope of these systems in the future.

Conclusion

In conclusion, Electrostatic Fluidized Bed Coating Systems represent a revolutionary technology in the coating industry. The systems offer several advantages over conventional coating methods, including high transfer efficiency, uniform coating, and cost-effectiveness. They are widely employed across various sectors, from automotive to electronics and household appliances.

Although there are challenges associated with this method, ongoing technological advancements hold great promise for the future of these systems. As our demand for more efficient and sustainable coating methods continues to grow, we can expect the Electrostatic Fluidized Bed Coating Systems to play an increasingly prominent role in meeting these needs.