Explore the workings of Electrostatic Chucks (ESCs), their types, applications, advantages, and future prospects in high-tech industries.

Introduction to Electrostatic Chucks

Often found in sophisticated equipment used in the world of manufacturing and technology, the Electrostatic Chuck (ESC) is an integral device that warrants detailed understanding. For those seeking to delve into its workings, applications, and relevance in the modern world, this article serves as an introductory guide.

What are Electrostatic Chucks?

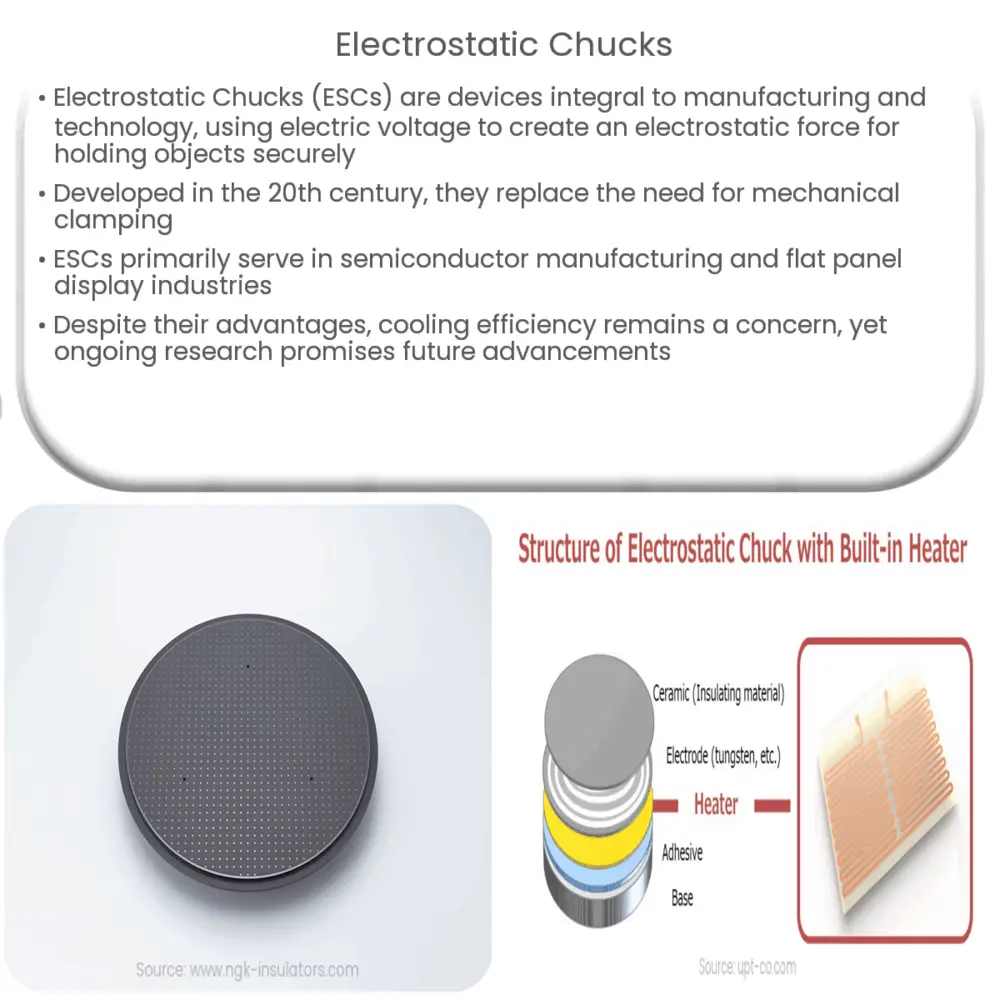

Developed in the late 20th century, the Electrostatic Chuck was created to address the need for a reliable method to hold objects for processing in various industries. Electrostatic chucks are devices that use electric voltage to generate an electrostatic force. This force serves to attract and hold an object securely, providing a firm grip without the need for mechanical clamping or vacuum holding.

The Mechanics of Electrostatic Chucks

- Materials and Design: Electrostatic chucks are generally made of ceramic or other similar materials. They consist of two significant parts – the dielectric layer and the electrode layer. The design, shape, and size of an ESC can vary according to specific applications.

- Functioning: When voltage is applied to the electrodes, it generates an electric field that induces opposite charges on the chuck and the object to be held. The resulting electrostatic attraction holds the object firmly on the chuck.

Types of Electrostatic Chucks

There are two principal types of electrostatic chucks:

- Johnsen-Rahbek (JR) Electrostatic Chuck: This type operates based on the principle of “electrostatic adhesion”. It uses a high voltage but a low electric field, making it capable of holding even objects with non-uniform shapes.

- Coulombic Electrostatic Chuck: Named after the French physicist Charles-Augustin de Coulomb, this type functions on the principle of Coulombic attraction. It uses a high electric field but a lower voltage compared to JR type chucks.

These types of chucks have specific pros and cons, with their usage being dictated by the demands of the application at hand.

Applications of Electrostatic Chucks

Electrostatic chucks find their primary application in semiconductor manufacturing and flat panel display industries, where they are employed to hold silicon wafers and glass substrates during the manufacturing process. However, their use extends far beyond these industries, offering a host of benefits in various contexts.

Advanced Applications of Electrostatic Chucks

In addition to their primary uses, electrostatic chucks are also used in electron microscopes and lithography systems. In lithography, the chuck’s even distribution of electrostatic force provides an extremely flat surface, ensuring high accuracy during the patterning process.

Furthermore, as we progress into the era of nanotechnology, ESCs are finding applications in nanofabrication processes. Their ability to hold extremely small and delicate objects without physical contact makes them an invaluable tool in this field.

Advantages of Electrostatic Chucks

- Non-contact Clamping: Since electrostatic chucks use electrostatic force for clamping, they do not cause physical stress or damage to the objects being held, making them ideal for delicate materials.

- Uniform Force Distribution: The electrostatic force exerted by the chuck is evenly distributed across the surface, reducing deformation and ensuring better accuracy.

- Scalability: Electrostatic chucks are highly scalable. They can be used to hold objects ranging from large panels to minuscule wafers, making them versatile for various applications.

Challenges and Future Perspectives

Despite their numerous advantages, ESCs do have some limitations. The cooling efficiency of electrostatic chucks, especially in high power applications, is a significant concern. Moreover, the electrostatic force may cause charging damage to certain types of materials.

Researchers are tirelessly working on these issues and developing new methods to improve the performance and versatility of electrostatic chucks. The future of ESCs is promising, with their potential uses expanding in various domains of manufacturing and technology.

Conclusion

In conclusion, electrostatic chucks play an invaluable role in multiple high-tech industries, with their importance growing with each technological advancement. As we strive towards higher precision and smaller scales in manufacturing and technology, the relevance and applications of electrostatic chucks are expected to broaden. By understanding the principle, benefits, and challenges of ESCs, we gain valuable insights into a tool that shapes our technological landscape, accelerating us towards the future.