Electrochemical gas sensors detect gas levels with high sensitivity and selectivity, offering low power consumption and rapid response times.

Electrochemical Gas Sensors: An Overview

Introduction

Gas detection and monitoring are essential in a variety of industrial applications to ensure safety, maintain process efficiency, and comply with environmental regulations. Electrochemical gas sensors are a popular choice for many applications due to their high sensitivity, selectivity, and low power consumption. This article provides an overview of the principles behind electrochemical gas sensors, their advantages, and some of the common applications in which they are used.

Principles of Electrochemical Gas Sensing

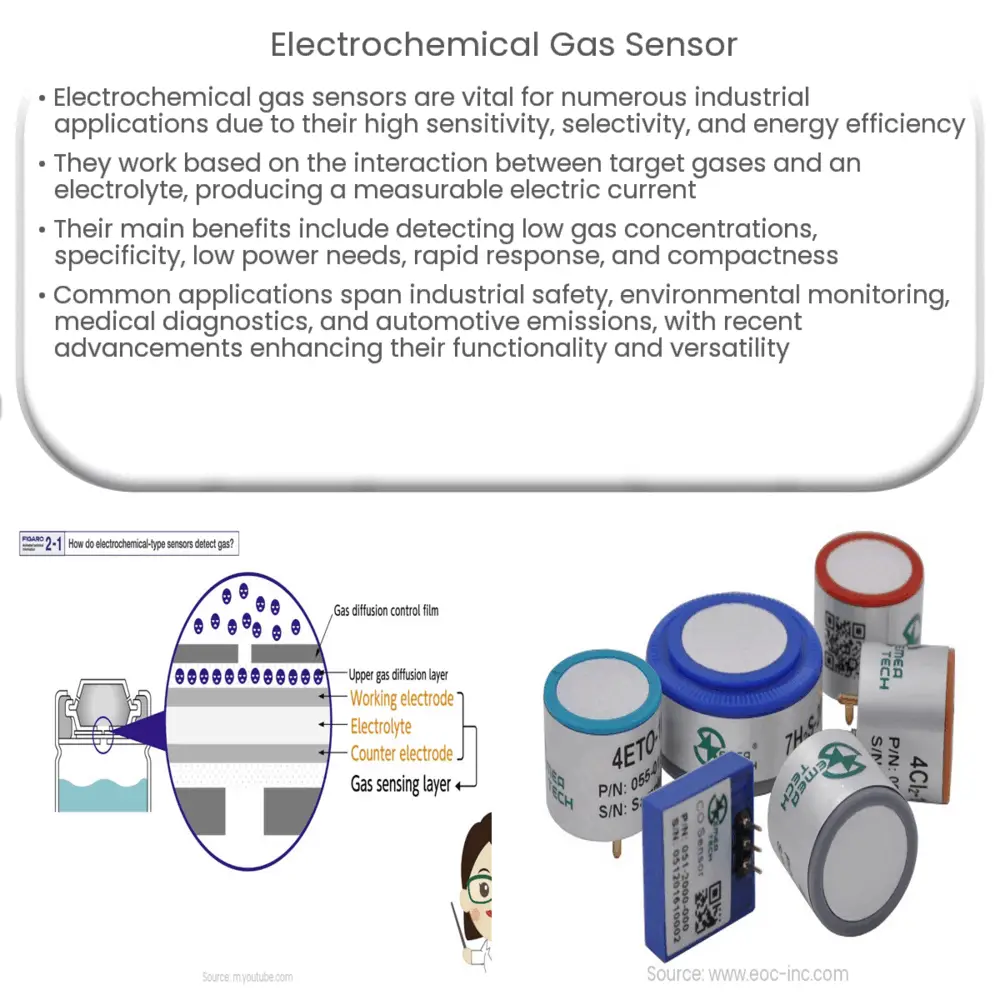

Electrochemical gas sensors operate based on the interaction between a target gas and an electrolyte within the sensor. The target gas diffuses through a gas-permeable membrane and reacts with the electrolyte, resulting in the generation of an electric current. This current is proportional to the concentration of the target gas and can be measured to provide an accurate reading of gas concentration.

There are three main components in an electrochemical gas sensor: the working electrode, the counter electrode, and the reference electrode. The working electrode is where the target gas reacts with the electrolyte, generating a current. The counter electrode is responsible for maintaining the electrochemical balance within the sensor by providing an equal and opposite current. The reference electrode provides a stable reference potential, which allows for accurate measurement of the current generated at the working electrode.

Advantages of Electrochemical Gas Sensors

Electrochemical gas sensors offer several advantages over other types of gas detection technologies:

- High sensitivity: Electrochemical sensors can detect low concentrations of target gases, making them suitable for applications requiring precise measurements.

- Selectivity: The sensors can be designed to respond specifically to a particular gas, reducing the likelihood of false alarms caused by interference from other gases.

- Low power consumption: These sensors typically require less power to operate compared to other gas detection technologies, making them ideal for portable or battery-operated devices.

- Fast response times: Electrochemical sensors can respond quickly to changes in gas concentration, allowing for real-time monitoring of gas levels.

- Compact size: The small size of electrochemical sensors enables easy integration into various devices and systems.

Common Applications of Electrochemical Gas Sensors

Due to their versatility and performance, electrochemical gas sensors are used in a wide range of applications, including:

- Industrial safety: Monitoring of toxic gases such as hydrogen sulfide, carbon monoxide, and ammonia in industries such as oil and gas, chemical manufacturing, and wastewater treatment.

- Environmental monitoring: Measurement of air pollutants like ozone, nitrogen dioxide, and sulfur dioxide for compliance with environmental regulations and assessment of air quality.

- Medical diagnostics: Detection of gases such as nitric oxide and carbon dioxide in breath analysis for the diagnosis and monitoring of various medical conditions.

- Automotive emissions: Monitoring of exhaust gases, including nitrogen oxides and hydrocarbons, to ensure compliance with emission standards and improve vehicle performance.

As advances in electrochemical sensing technology continue, we can expect to see even more applications and improvements in the performance of these versatile sensors.

Recent Developments in Electrochemical Gas Sensors

Continuous research and development efforts have led to significant advancements in electrochemical gas sensing technology. Some of these recent developments include:

- Nanomaterials: The use of nanomaterials, such as metal oxides, carbon nanotubes, and graphene, has significantly improved the sensitivity and selectivity of electrochemical gas sensors. These materials enhance the electrocatalytic activity and increase the effective surface area of the electrodes, resulting in better gas detection performance.

- Miniaturization: The development of microelectromechanical systems (MEMS) technology has enabled the creation of miniaturized electrochemical gas sensors. These compact sensors can be integrated into wearable devices, smartphones, and other portable electronics for real-time, on-site gas monitoring.

- Wireless connectivity: The integration of wireless communication capabilities, such as Bluetooth and Wi-Fi, allows electrochemical gas sensors to transmit data to remote monitoring systems and cloud-based platforms. This enhances the accessibility and flexibility of gas monitoring solutions.

- Improved manufacturing techniques: Advances in manufacturing processes, such as screen-printing and thin-film deposition, have reduced the cost and complexity of producing electrochemical gas sensors, making them more accessible to a wider range of applications.

Maintenance and Calibration of Electrochemical Gas Sensors

Proper maintenance and calibration are crucial for ensuring the accuracy and reliability of electrochemical gas sensors. Over time, the performance of the sensor may be affected by factors such as electrode degradation, electrolyte evaporation, and membrane contamination. Therefore, periodic calibration is necessary to account for these changes and maintain accurate readings.

Calibration typically involves exposing the sensor to a known concentration of the target gas and adjusting the sensor output to match the expected reading. This process can be performed manually or automatically using calibration equipment. Additionally, some advanced electrochemical gas sensors incorporate self-calibration features to minimize the need for manual intervention and simplify maintenance.

Conclusion

Electrochemical gas sensors offer numerous advantages, such as high sensitivity, selectivity, low power consumption, and fast response times, making them an ideal choice for a wide range of applications. Recent developments in nanomaterials, miniaturization, wireless connectivity, and manufacturing techniques have further improved the performance and accessibility of these sensors. With proper maintenance and calibration, electrochemical gas sensors can provide accurate and reliable gas detection solutions for industrial safety, environmental monitoring, medical diagnostics, and automotive emissions applications, among others.