Explore the workings, advantages, and applications of Doubly-Fed Induction Generators (DFIGs), their role in renewable energy, and future prospects.

Introduction to Doubly-Fed Induction Generators (DFIG)

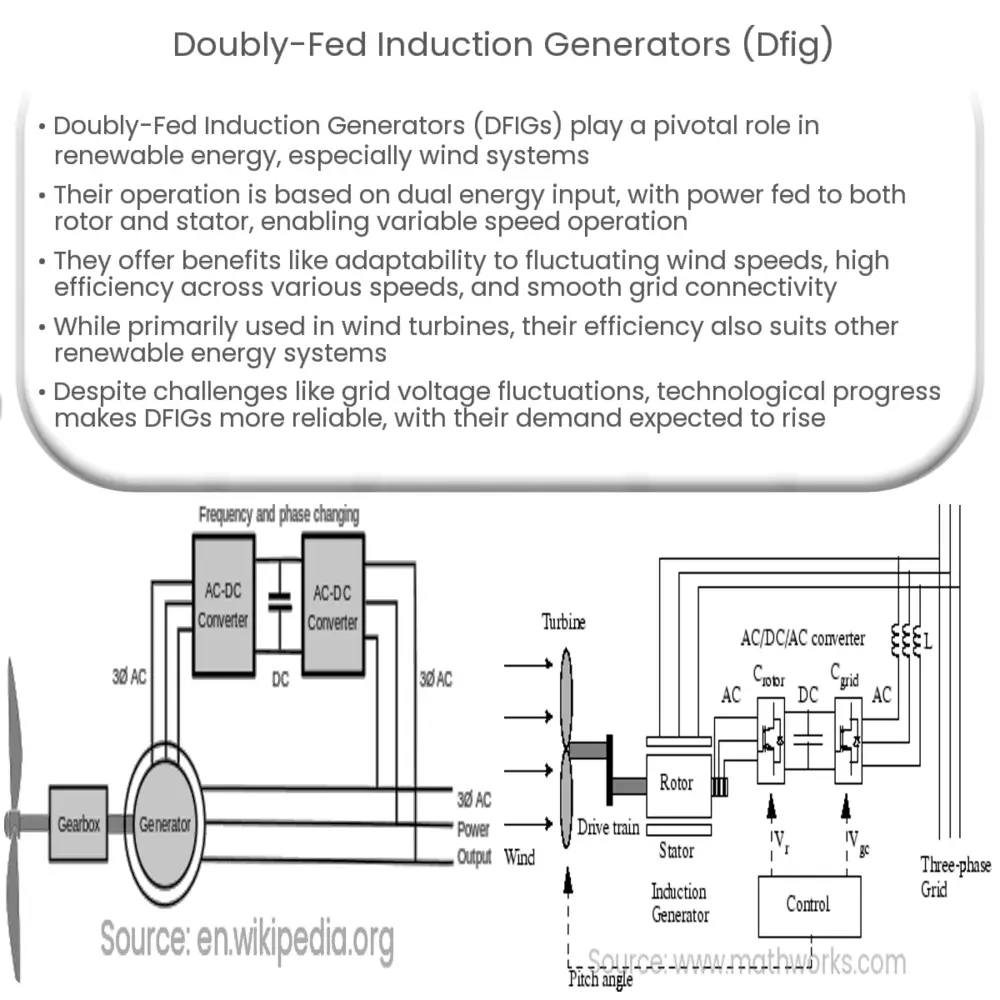

Doubly-Fed Induction Generators, or DFIGs, are a type of electrical generator that play a significant role in the realm of renewable energy, particularly wind energy systems. Their unique characteristics and advantages make them a preferred choice for many wind turbine systems.

Principle of Operation

The fundamental principle of a DFIG revolves around the concept of dual energy input, as the name suggests. Unlike a traditional generator, a DFIG is fed with electrical power on both the rotor and stator sides, allowing for two-way power flow. This is achieved by means of a rotor winding which is connected to the grid via a back-to-back converter, allowing the rotor to operate at variable speed.

Advantages of DFIGs

- Flexibility: DFIGs have a distinct operational advantage due to their ability to operate at variable speeds. This allows them to adapt to fluctuating wind speeds, making them ideal for wind energy applications.

- Efficiency: DFIGs can maintain a high level of efficiency over a wider range of speeds compared to traditional induction generators. This is because power is fed into both the stator and rotor, increasing the generator’s ability to convert mechanical power into electrical power.

- Grid Connection: Owing to the back-to-back converter, DFIGs can smoothly connect and disconnect from the grid, ensuring stability and continuity in power supply.

Applications of DFIGs

While DFIGs have found their primary usage in wind turbines, their flexible and efficient operation means they are also suitable for other renewable energy systems, including small hydro and tidal energy generation plants. The ability to operate across a wide range of speeds without a significant loss in efficiency is a characteristic highly desired in these applications.

Construction of DFIGs

The construction of a DFIG primarily consists of two parts – the stator and rotor. The stator is similar to a standard induction generator, consisting of a three-phase winding. The rotor, on the other hand, is a wound rotor, connected to the grid via slip rings and a converter. This design allows for variable speed operation and two-way power flow.

Working Mechanism of DFIGs

The working mechanism of a DFIG involves a rotor that can rotate at different speeds, either faster or slower than the stator magnetic field. The rotor speed is controlled by adjusting the frequency of the current fed to the rotor winding through the back-to-back converter. This converter also helps in controlling the power factor at which the generator operates, contributing to a stable grid operation.

Control of DFIGs

DFIGs are usually controlled by a two-axis reference frame model known as the dq model. This model, based on Park’s transformation, simplifies the control of the rotor currents. In this model, the d-axis controls the active power and the q-axis controls the reactive power. This dual control mechanism plays a crucial role in maintaining grid stability and in optimizing power extraction, particularly in wind power generation.

Challenges and Future Prospects

Despite their many advantages, DFIGs also have certain challenges. For instance, DFIGs are susceptible to voltage sags and swells from the grid, which can potentially cause instability. However, technological advancements are continually addressing these issues with advanced control strategies and robust converter designs.

Future prospects for DFIGs look promising. With the increasing focus on renewable energy and the urgent need for more efficient and flexible generation systems, the demand for DFIGs is expected to grow. Research into increasing their power density, improving control strategies, and enhancing their robustness to grid disturbances is actively underway.

Conclusion

In conclusion, Doubly-Fed Induction Generators (DFIGs) have emerged as a significant player in the renewable energy sector, particularly in wind energy generation. Their unique ability to operate at variable speeds, their high efficiency, and smooth grid connectivity make them a preferred choice in this domain. Though there are challenges in their implementation, continuous advancements in technology and control strategies are making DFIGs increasingly reliable and efficient. As we transition towards more sustainable energy sources, DFIGs are likely to play a critical role in powering our future.