Explore the basics of conductivity sensors, their working principles, types, applications, advantages, and limitations in our comprehensive guide.

Introduction to Conductivity Sensors

Conductivity sensors are instrumental devices widely used across various industries and research fields. Their primary function is to measure the ability of a solution to conduct electric current, which directly correlates with the concentration of ions present in the solution. This article aims to delve deeper into the concepts, applications, and functioning of conductivity sensors.

Concept of Conductivity

Understanding the principle of conductivity is crucial for grasping how conductivity sensors work. Conductivity, denoted by the Greek letter Sigma (σ), is the measure of a substance’s ability to conduct electric current. In liquids, this ability is typically due to the presence of ions.

In a nutshell, higher the ion concentration, higher the conductivity, and vice versa. Therefore, measuring conductivity can provide valuable insight into the purity of water or the concentration of various solutions, which finds applications in a plethora of sectors.

Working Principle of Conductivity Sensors

- The core functionality of a conductivity sensor is based on Ohm’s Law, which states that the current through a conductor between two points is directly proportional to the voltage across the two points.

- Conductivity sensors often comprise two electrodes placed in a solution, connected to a voltage source. When voltage is applied, the current is carried across the electrodes by ions present in the solution.

- The sensor then measures this current to calculate the conductivity of the solution.

Types of Conductivity Sensors

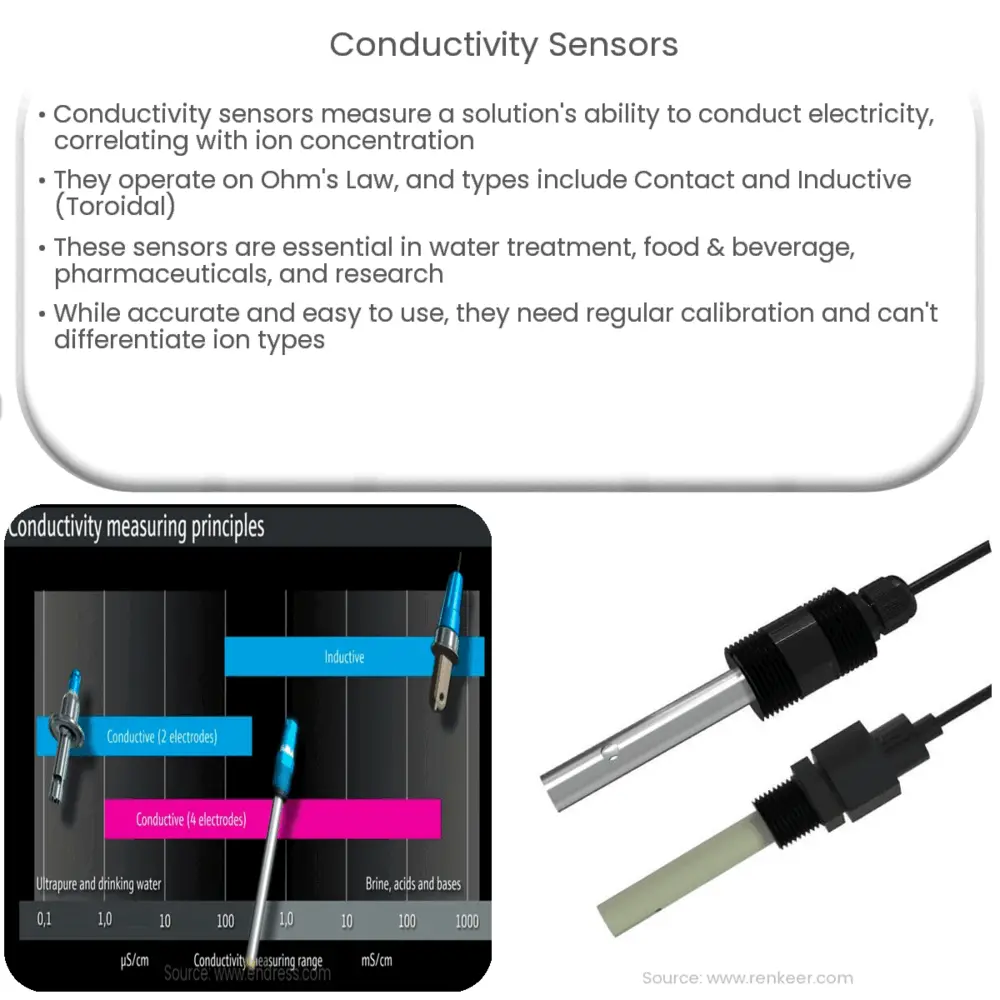

Conductivity sensors can be broadly categorized into two types: Contact and Inductive or Toroidal.

- Contact Sensors: These sensors use direct contact with the solution to measure conductivity. They comprise two or four electrodes immersed in the solution. While they are simpler and more economical, they can suffer from polarization and coating issues in high conductivity or dirty solutions.

- Inductive Sensors: Also known as toroidal sensors, they are designed to address the shortcomings of contact sensors. They feature a pair of wire-wound coils (toroids) encapsulated in a non-conductive body and do not come in direct contact with the solution. This design makes them resistant to fouling and ideal for dirty or high conductivity solutions.

Applications of Conductivity Sensors

Conductivity sensors find extensive applications in diverse sectors due to their ability to provide critical information regarding the quality and characteristics of different solutions.

- Water Treatment: In water treatment plants, conductivity sensors help assess the effectiveness of the filtration system by detecting the concentration of dissolved salts before and after the process.

- Food and Beverage Industry: They are used to ensure the correct concentration of ingredients in various food and beverage products.

- Pharmaceuticals: In the pharmaceutical industry, these sensors verify the purity of water used in manufacturing processes.

- Research Labs: Conductivity sensors are standard tools in research laboratories for performing a variety of experiments and studies related to chemical solutions.

Advantages and Limitations

Like any technology, conductivity sensors come with their strengths and limitations.

- Advantages: These sensors offer quick and accurate measurements, are easy to use and maintain, and are suitable for a wide range of solutions. Inductive sensors, in particular, show high resistance to fouling and corrosion, making them ideal for harsh environments.

- Limitations: On the downside, conductivity sensors can be sensitive to temperature fluctuations, requiring regular calibration. Contact sensors can face polarization and coating issues in high conductivity or dirty solutions. Also, these sensors cannot differentiate between different types of ions in a solution.

Conclusion

In conclusion, conductivity sensors are integral tools in numerous industries, owing to their ability to measure the conductivity of various solutions. While they do have their constraints, the benefits they offer in terms of precision, usability, and wide-ranging applications far outweigh these limitations. The continuous advancements in sensor technology promise to further enhance their capabilities and widen their applicability in the future.