Explore the world of conductivity meters, their applications in various industries, factors influencing their readings, and tips for maintenance.

Introduction to Conductivity Meters

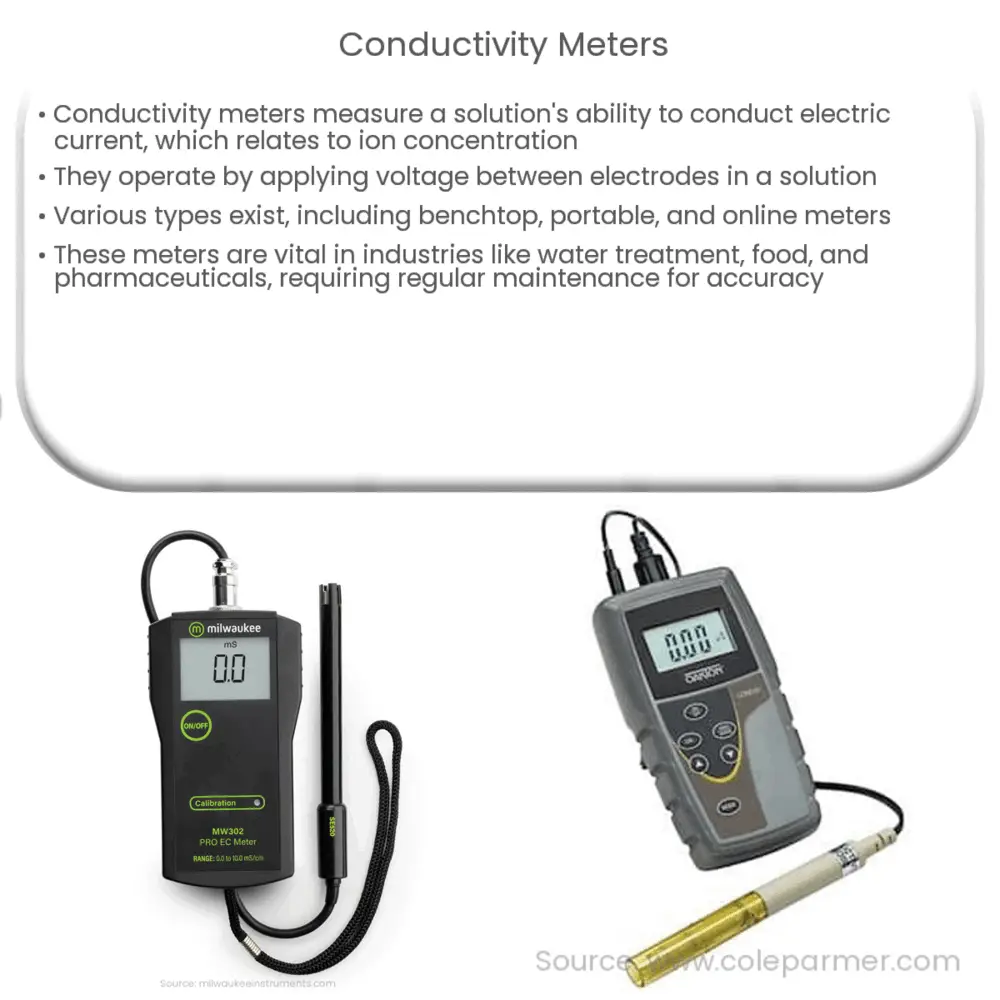

Conductivity meters are indispensable tools in a wide variety of industries and research fields, including water quality testing, aquarium maintenance, hydroponics, beverage production, and environmental monitoring. They measure the ability of a solution to conduct an electric current, a characteristic directly related to the ion concentration in the solution.

Principles of Operation

A conductivity meter operates based on a simple yet effective scientific principle. It applies a voltage between two electrodes immersed in a solution. The resulting current that passes through the solution is directly proportional to the solution’s conductivity. The meter measures this current and calculates the conductivity.

Key Components of a Conductivity Meter

- Electrodes: These are usually made of platinum or stainless steel. They are designed to create an electric field in the solution.

- Thermometer: Since temperature can affect conductivity, most meters have a built-in thermometer to measure and correct the readings.

- Display: This shows the conductivity reading, often in microsiemens per centimeter (µS/cm).

Types of Conductivity Meters

Conductivity meters come in various forms, each suited to different applications. Here are the main types:

- Benchtop Meters: These are usually larger and more precise, perfect for laboratory use.

- Portable or Handheld Meters: These are compact, rugged, and suitable for field use.

- Online or In-line Meters: These are installed in a process stream for real-time monitoring.

The Importance of Conductivity Measurements

Conductivity measurements are crucial for assessing water purity and the overall health of aquatic ecosystems. The level of dissolved salts, often referred to as total dissolved solids (TDS), correlates to conductivity and is a key indicator of water quality. Further, conductivity meters help in detecting changes in a solution’s composition, making them essential in industries like food and beverage production, where consistency is paramount.

Conductivity Meters in Various Industries

Conductivity meters play a significant role in a multitude of industries:

- Water Treatment: They monitor the efficiency of desalination, demineralization, or reverse osmosis systems by checking the conductivity of output water.

- Food and Beverage: By tracking conductivity, manufacturers can assure the quality and consistency of their products.

- Aquaculture: Conductivity meters are used to monitor the salt levels in water, vital for the survival and growth of marine species.

- Pharmaceuticals: Conductivity measurement is a non-destructive method to check the purity of water used in manufacturing drugs.

Factors Influencing Conductivity Readings

Several factors can impact the accuracy of a conductivity meter’s readings. One primary factor is temperature. Since conductivity increases with temperature, most modern meters have a temperature compensation feature to ensure accurate readings across a range of temperatures. Also, the presence of certain ions may disproportionately influence conductivity. For example, a small amount of ionized calcium can have a larger effect on conductivity than a similar amount of sodium.

Caring for Conductivity Meters

Like any precision instrument, conductivity meters require regular maintenance to ensure accuracy. This includes regular calibration against known standards and cleaning the electrodes to prevent build-up of residue. Some meters also have replaceable electrodes, prolonging the instrument’s lifespan and functionality.

Conclusion

In conclusion, conductivity meters are vital instruments in a wide range of applications. They provide a quick and accurate method for measuring the ion concentration in solutions, critical for assessing water purity and maintaining quality control in various industries. Despite their complex functionality, they are easy to use and maintain, making them an essential tool in any professional’s toolkit. As technology advances, we can expect further improvements in conductivity meter accuracy, portability, and user-friendliness, leading to even broader applications in the future.