Explore the workings, construction, advantages, and applications of Capacitor-Start Induction Motors in our comprehensive guide.

Introduction to Capacitor-Start Induction Motors

A Capacitor-Start Induction Motor is a type of electric motor widely used in various domestic, industrial, and commercial applications due to its remarkable features. These motors are known for their impressive starting torque and the ability to operate with a single phase power source.

Working Principle

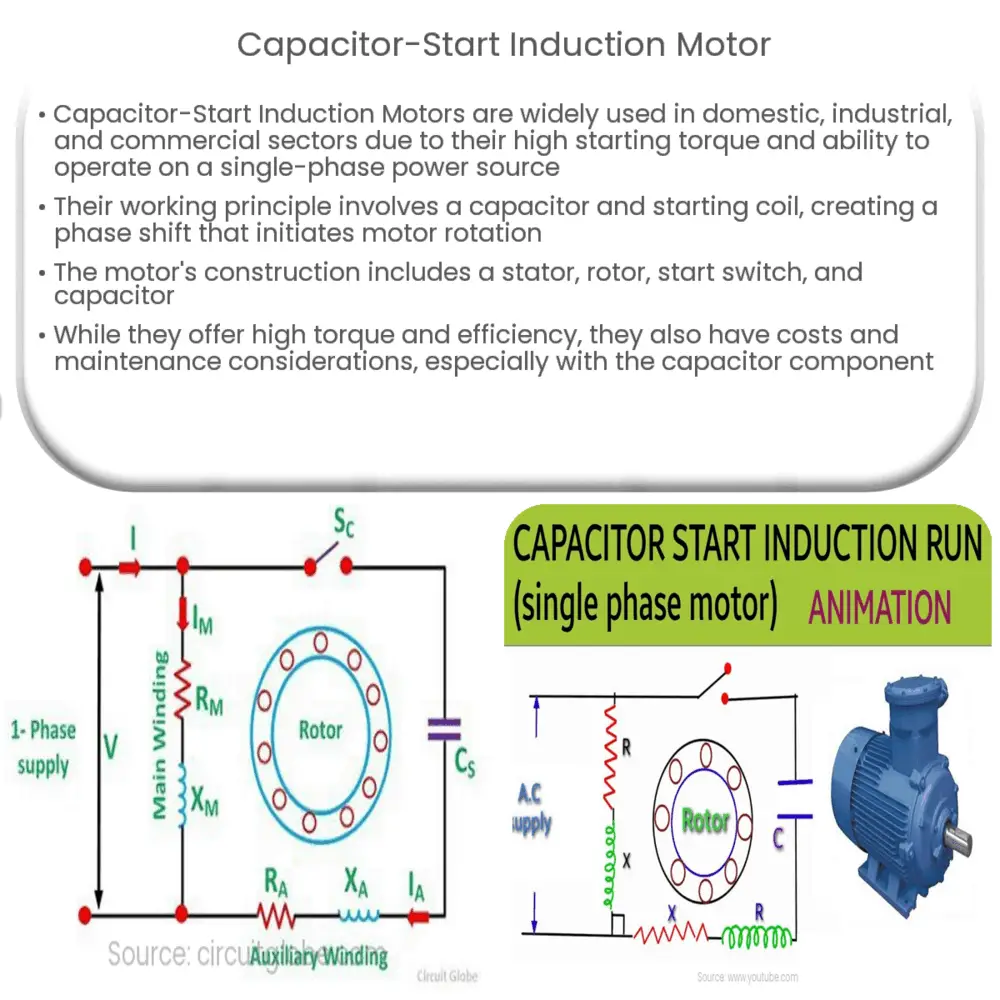

The working principle of a Capacitor-Start Induction Motor involves a capacitor and a starting coil. The motor is designed with two windings: the main winding and an auxiliary or starting winding. Both windings are placed in the stator, and the capacitor is connected in series with the starting winding. This combination creates a phase shift between the currents in the two windings, resulting in a rotating magnetic field that initiates the motor’s rotation.

- Main Winding: This is directly connected to the power supply and generates a magnetic field.

- Starting Winding: This is placed 90 degrees electrically apart from the main winding and is connected to the power supply via a capacitor.

Construction of Capacitor-Start Induction Motors

A Capacitor-Start Induction Motor is constructed with a stator, a rotor, a start switch, and a capacitor.

- Stator: The stator includes the main and the auxiliary winding. It is stationary and forms the external part of the motor.

- Rotor: The rotor is the rotating part of the motor. It is typically of the squirrel cage type.

- Start Switch: This switch disconnects the start winding and the capacitor when the motor reaches about 75% to 80% of its full speed.

- Capacitor: The capacitor is in series with the start winding and creates a phase difference between the currents in the start and main windings.

The construction design and working principle of Capacitor-Start Induction Motors allow them to generate high starting torque, making them suitable for a variety of applications where a high starting torque is required.

Applications of Capacitor-Start Induction Motors

Capacitor-Start Induction Motors are commonly used in applications where the motor must start quickly. These include air conditioners, fans, pumps, power tools, and various types of domestic and industrial equipment.

Despite their wide range of applications, these motors have certain limitations and considerations. In the following section, we will discuss these aspects, including the advantages and disadvantages of Capacitor-Start Induction Motors, their performance characteristics, and the factors to consider when selecting these motors.

Advantages and Disadvantages of Capacitor-Start Induction Motors

Like any device, Capacitor-Start Induction Motors come with their own set of advantages and disadvantages. Understanding these can help in making informed decisions regarding their application.

- Advantages:

- High Starting Torque: With a capacitor in the starting winding, these motors generate a high starting torque, suitable for heavy-load starting conditions.

- Efficient Operation: Capacitor-Start Induction Motors operate efficiently with a single phase power source, making them suitable for domestic and commercial applications.

- Simple Design: The design of these motors is relatively simple, making them easy to manufacture and maintain.

- Disadvantages:

- Cost: The addition of a capacitor increases the overall cost of the motor.

- Maintenance: The capacitor may require periodic replacement, adding to the maintenance requirements.

- Not Suitable for Variable Speed Applications: These motors are not designed for variable speed applications due to their starting mechanism.

Performance Characteristics

The performance of a Capacitor-Start Induction Motor is influenced by several factors, including the size and type of the capacitor, the voltage and frequency of the power supply, and the load conditions. Typically, these motors demonstrate high starting torque, moderate starting current, and good efficiency under full-load conditions.

Selection Considerations

When selecting a Capacitor-Start Induction Motor for a specific application, consider the following:

- Starting Torque Requirements: Choose a motor that meets the starting torque requirements of the application.

- Power Supply: Ensure the motor is compatible with the available power supply in terms of voltage and frequency.

- Maintenance Capacity: Assess the ability to perform the required maintenance, including capacitor replacement.

Conclusion

Capacitor-Start Induction Motors are versatile and efficient, offering high starting torque and robust performance for a wide range of applications. Despite their disadvantages, their simplicity, power, and efficiency make them an excellent choice for many domestic, commercial, and industrial needs. Understanding their working principle, construction, and performance characteristics can help in making the right selection for specific applications, ensuring efficient operation and longevity.