Explore the intricacies of blade fuses – their construction, types, ratings, and importance in automotive electrical systems.

Understanding Blade Fuses

A blade fuse is a crucial component of many electrical systems, particularly those in the automotive industry. It plays a pivotal role in protecting the electrical circuits by preventing the flow of excess current that could potentially lead to circuit damage.

The Construction and Functionality

The main body of a blade fuse is generally comprised of two metal prongs known as blades, and a plastic housing which is often transparent. The transparent plastic casing allows for easy inspection of the fuse wire or conductor strip. The key component is the thin metal strip located in the centre, which is designed to melt when subjected to excessive current, thus breaking the circuit and preventing further damage.

- Blades: These are the metal parts on either side of the fuse that plug into the fuse holder or socket.

- Plastic Body: The plastic housing provides insulation, preventing short-circuits or inadvertent contact with the metal strip.

- Metal Strip: This is the safety component that melts under excessive electrical load, effectively cutting off the power.

Types of Blade Fuses

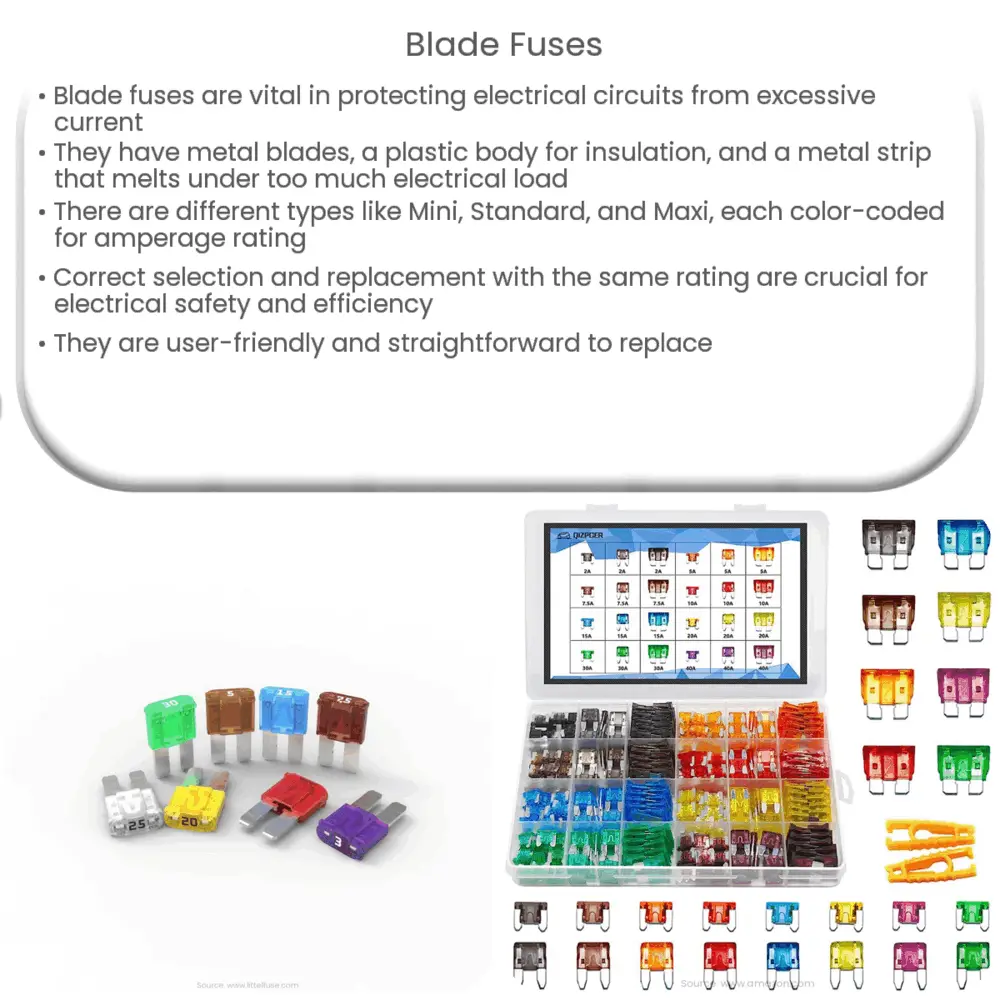

Blade fuses come in different shapes and sizes, designed for different applications and current ratings. The three most common types are the Mini, Standard, and Maxi blade fuses.

- Mini Blade Fuses: As the name suggests, these fuses are compact and typically used in newer vehicles for space efficiency.

- Standard Blade Fuses: These are the most common type of blade fuses, used in a wide variety of vehicles.

- Maxi Blade Fuses: These are larger and designed to handle higher currents, often used in more demanding electrical systems.

Each type of fuse is color-coded according to its rated current, enabling easy identification. For instance, a 10-ampere standard blade fuse will be red, while a 20-ampere one will be yellow.

Blade Fuses Ratings and Specifications

Blade fuses are classified by their amperage rating, which signifies the maximum amount of current the fuse can handle before it blows or breaks the circuit. This rating is usually imprinted on the top of the fuse for easy identification. Moreover, the color-coding system aids in determining the correct replacement fuse.

The voltage rating is another important specification. This indicates the maximum voltage the fuse can safely interrupt. Common voltage ratings for automotive blade fuses are 32V and 58V, but it’s always crucial to refer to your device’s user manual or consult a professional for the correct specifications.

The Importance of Choosing the Correct Blade Fuse

Selecting the appropriate blade fuse is essential for the safety and longevity of your electrical system. Using a fuse with a too-high amperage rating may not protect the circuit effectively, while a too-low amperage rating could result in frequent, unnecessary fuse blows. Therefore, always ensure to replace a blown fuse with another of the exact same rating.

Replacing Blade Fuses

Blade fuses are user-friendly and straightforward to replace. Once the blown fuse is identified, it can simply be pulled out from the fuse holder and replaced with a new one of the same rating. Always remember to switch off the power supply or disconnect the battery before replacing a fuse to avoid any risk of electric shock.

Conclusion

In conclusion, blade fuses are an indispensable safety component in many electrical systems, notably in automotive applications. They are designed to protect these systems from excessive current that could result in damage. With a wide range of types and ratings, it’s important to understand how to identify and choose the appropriate blade fuse for your specific application. Regular checks and timely replacements of blown fuses will go a long way in maintaining the health and efficiency of your electrical system.