Explore the innovative world of air-core motors: their design, operation, applications, challenges, and future potential in robotics and aerospace.

Air-Core Motors: Pioneers of the New Generation

The world of motors has seen numerous advancements over the years, but one that stands out for its uniqueness and potential is the ‘Air-Core Motor’. By discarding conventional design norms, air-core motors promise a transformative approach to motor technology.

Understanding the Concept

At its heart, an air-core motor, as the name suggests, does not have a typical iron core. Instead, the coil windings are suspended in air. This structure eliminates the inherent inefficiencies found in conventional motors, such as eddy currents and hysteresis losses that occur due to the presence of a magnetic core. The air-core motor also provides advantages such as low inertia and high-speed capabilities, making it particularly suitable for applications requiring rapid response times.

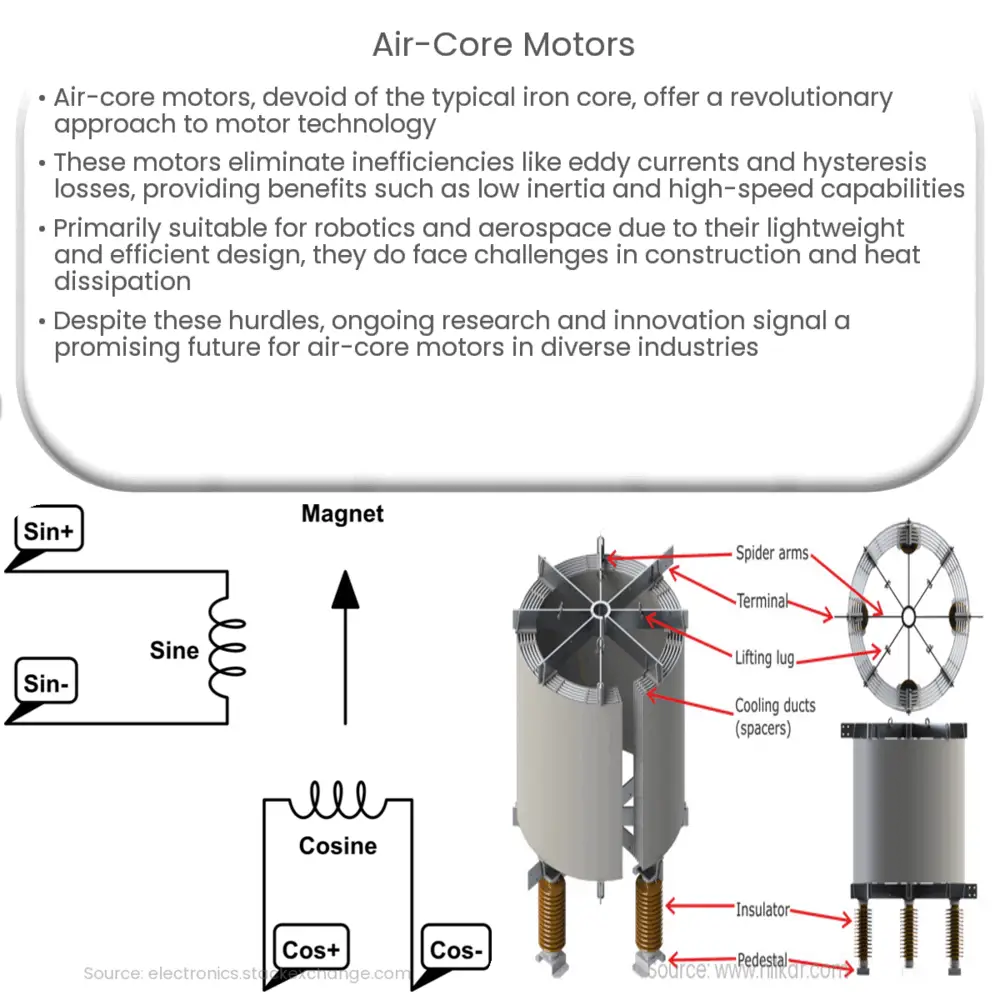

Components of an Air-Core Motor

- Stator: The stationary part of the motor, comprising a set of coils. These coils create an electromagnetic field when an electric current is passed through them.

- Rotor: The rotating part of the motor. In an air-core motor, the rotor is typically a permanent magnet.

- Windings: These are the conductive wires wound around the stator. The windings in an air-core motor are suspended in air, hence the name.

Without the need for an iron core, the air-core motor design reduces the weight and the overall complexity of the motor. This has led to increased interest in its potential for applications in various industries, such as aerospace and robotics.

Principle of Operation

The working principle of an air-core motor is the same as that of a standard electric motor. An electric current is supplied to the windings of the stator, which generates a magnetic field. This magnetic field interacts with the field from the permanent magnet in the rotor, causing it to rotate. The key difference, however, lies in the absence of an iron core, leading to different performance characteristics and advantages.

Applications and Advantages

The potential of air-core motors is vast, but the most prominent application lies in the field of robotics. Given their lightweight construction, quick response times, and high-speed operation, they are ideally suited for use in robotic arms and other precision machinery. Their other benefits include lower energy consumption, minimal electromagnetic interference, and the absence of cogging torque, which is a common issue in traditional motors.

Air-core motors also find potential application in the aerospace industry. The lightweight design coupled with their efficiency makes them an attractive choice for applications such as drone propulsion and satellite positioning systems.

Challenges and Future Directions

While air-core motors bring numerous benefits, they also come with certain challenges. The primary challenge lies in the difficulty of construction due to the absence of a solid core to hold the windings. Ensuring stability and strength in the windings without a core to support them requires meticulous design and precision manufacturing processes.

Heat dissipation is another challenge. Traditional iron-core motors have the advantage of utilizing the core as a heat sink, helping to dissipate the heat generated during operation. In contrast, air-core motors require separate mechanisms to manage heat effectively, thereby adding to the complexity and cost of the system.

Potential Solutions

Despite these challenges, ongoing research and development efforts are continually improving the design and performance of air-core motors. Innovative manufacturing processes and materials, such as high-strength composites for the windings, are being explored. Similarly, advanced cooling solutions, like liquid cooling systems or advanced heat sink designs, are being investigated to tackle the heat dissipation issue.

The Future of Air-Core Motors

Given the unique benefits they offer, air-core motors hold significant potential for the future. As technology evolves and manufacturing processes improve, it is expected that the challenges facing air-core motors will be overcome. This could pave the way for their widespread adoption in industries such as robotics, aerospace, and even consumer electronics.

Conclusion

In conclusion, air-core motors represent a transformative shift in the field of motor technology. By eliminating the traditional iron core, these motors offer numerous advantages, including reduced weight, lower energy consumption, and minimal electromagnetic interference. While they do face challenges, such as construction complexity and heat management, ongoing research and development promise solutions that could catapult air-core motors into widespread use. As we look to a future increasingly defined by efficiency and innovation, the role of air-core motors in powering our world cannot be overstated.