Explore the functionality, types, and applications of magnetic bases, a crucial tool for precision measurement across various industries.

Magnetic Bases: A Detailed Overview

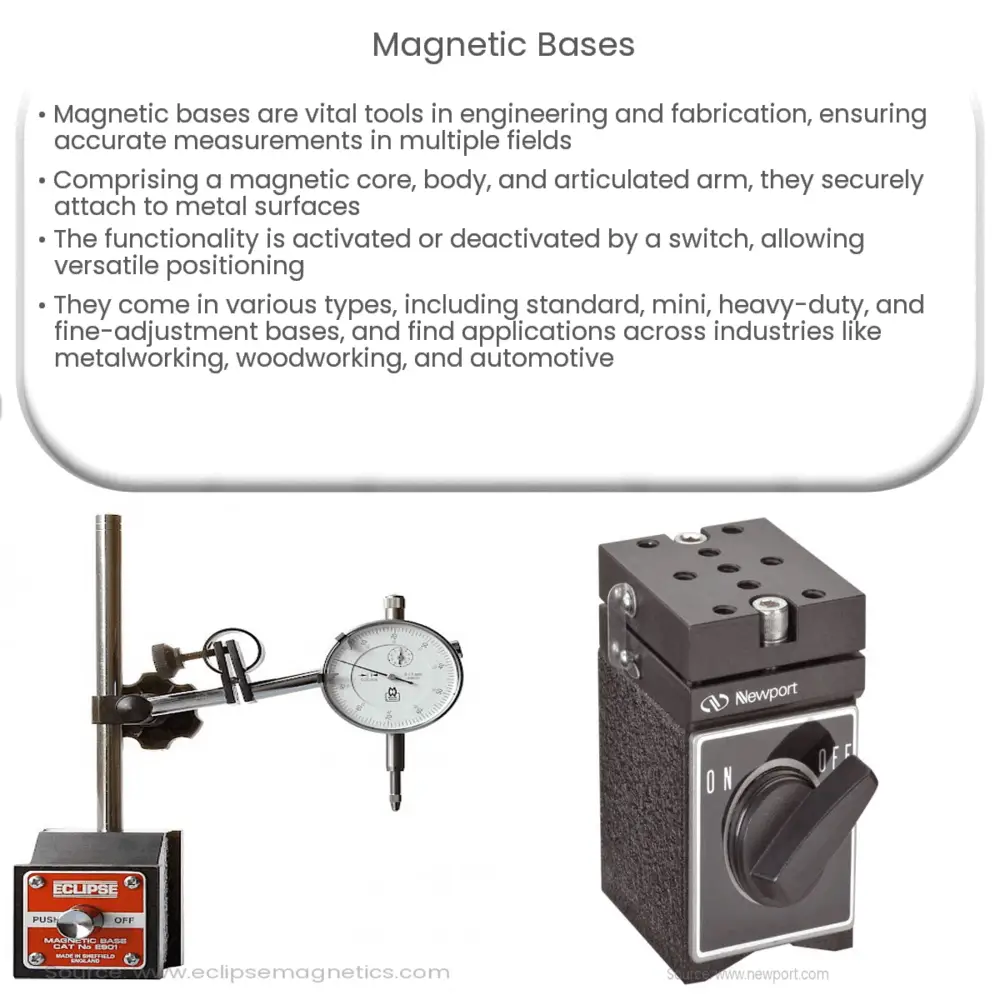

Magnetic bases, a crucial accessory in the field of engineering and fabrication, are an often overlooked but fundamentally vital tool. They serve as a reliable holding device for various precision measuring instruments, such as dial gauges, dial test indicators, and various types of probes.

Functioning on the principle of magnetism, these bases play a significant role in ensuring accuracy in several fields including automotive, metalworking, woodworking, and more. The ability of magnetic bases to attach to metal surfaces and hold measurement tools in a secure, stable position makes them invaluable for precision work.

Components of a Magnetic Base

A typical magnetic base consists of several key components. At the heart of its operation is a permanent magnet. This magnetic core is housed in a body, usually made from robust materials like steel or cast iron. The body often features an articulated arm, which is what holds the measurement tools. This arm can be precisely manipulated to set the tools in the desired position.

- The Magnetic Core: This is the element that imparts the magnetic property to the base. Most magnetic bases use either ferrite or rare earth magnets, known for their strong magnetic fields.

- The Body: Typically made from a non-magnetic material, the body houses the magnet and provides a mechanism to turn the magnetic field on or off. The base often has a V-shape or flat surface to adhere to both flat and round metal surfaces.

- The Arm: This part of the base allows for precise positioning of the instrument being held. The arm is often articulated, allowing for easy adjustments and lock-in-place ability for stability during measurement.

Operation of Magnetic Bases

The functionality of a magnetic base is simple, yet ingenious. By rotating a switch or knob located on the body, the magnetic field is activated or deactivated. When activated, the magnetic base clings firmly to ferrous surfaces, providing a secure hold for the attached tool. Conversely, when deactivated, the magnetic base detaches easily, allowing for quick repositioning or removal.

One of the greatest advantages of a magnetic base is its versatility. Thanks to the adjustable arm, the base can be arranged in almost any position, ensuring the measurement tool’s precise alignment.

Types of Magnetic Bases

Depending on the requirements of a specific task, different types of magnetic bases are available. The most common ones include:

- Standard Magnetic Bases: These bases typically include a single switch to engage or disengage the magnet, and an articulated arm for tool positioning.

- Mini Magnetic Bases: These smaller versions are ideal for tight spaces and smaller-scale precision tasks.

- Heavy-Duty Magnetic Bases: With stronger magnets and a more robust construction, these are designed for heavier tools and tougher work environments.

- Fine-adjustment Magnetic Bases: These come with an extra adjustment knob for fine-tuning the position of the held tool.

Applications of Magnetic Bases

Magnetic bases are widely used in various industries for precision measurement. Their robust design and ability to hold measurement tools steadily in place make them indispensable in many scenarios. Some of the key applications include:

- Metalworking: For precise measurements in machining, welding, and assembly tasks.

- Woodworking: For setting up and calibrating tools like routers and saws.

- Automotive Industry: For precise alignment and measurement of vehicle parts during assembly or repair.

- Research Laboratories: For holding probes, sensors, and other measurement devices.

Conclusion

In conclusion, magnetic bases are an indispensable tool in precision measurement across various industries. Their design, based on simple yet effective principles of magnetism, provides reliable and versatile tool-holding solutions. The various types of magnetic bases cater to a wide range of applications, from small-scale tasks in tight spaces to larger, more demanding industrial environments. Therefore, understanding the operation and selection of magnetic bases is crucial for professionals and hobbyists aiming for accuracy in their work.