A wire-wound potentiometer is a precise electrical component used to control voltage and current in various electronic circuits and systems.

Wire-Wound Potentiometer: An Overview

Introduction

A wire-wound potentiometer is a fundamental electrical component used in various electronic circuits to measure and control voltage and current. This versatile device has a wide range of applications, from controlling the volume in audio equipment to adjusting the speed of electric motors. This article aims to provide a comprehensive overview of wire-wound potentiometers, delving into their construction, working principle, advantages, and limitations.

Construction

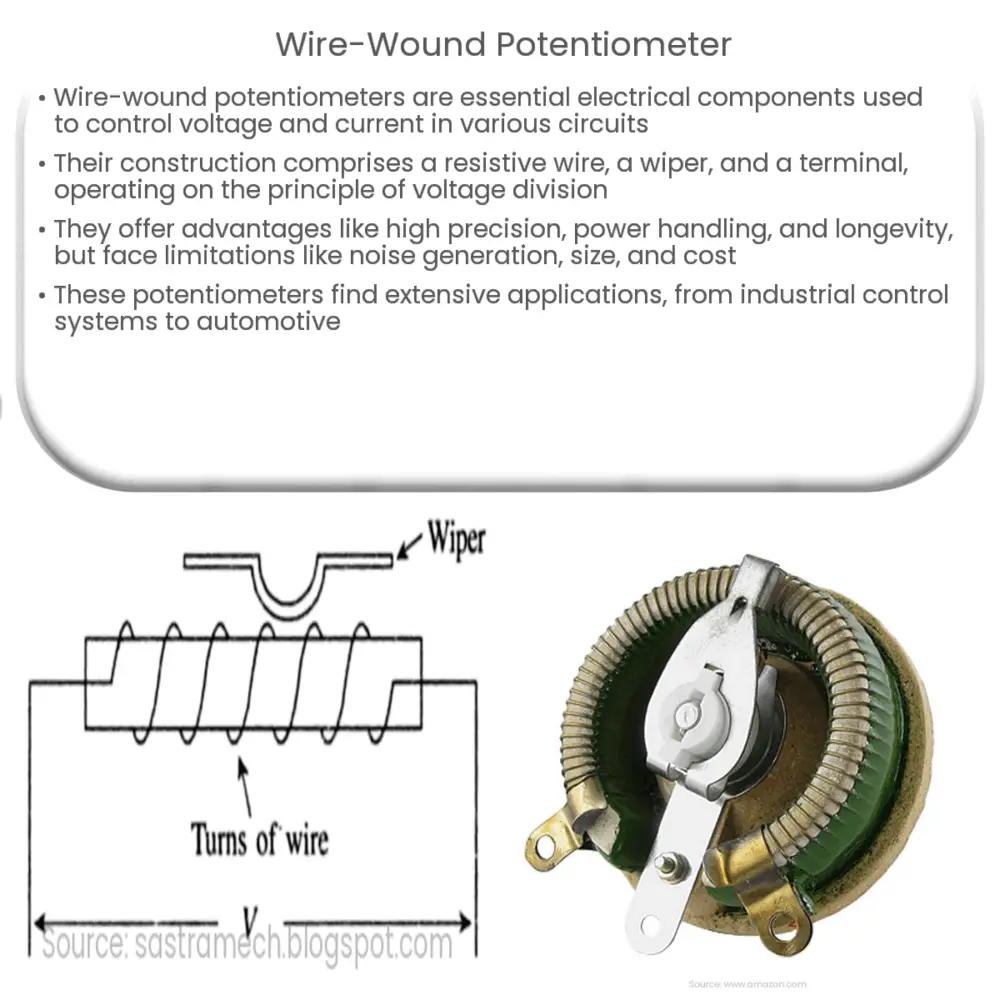

A wire-wound potentiometer consists of three main components: a resistive wire, a wiper, and a terminal. The resistive wire is usually made from a high-resistivity alloy like nickel-chromium (NiCr) or manganese-copper (MnCu), wrapped around a non-conductive core, typically made of ceramic or fiberglass. The wire’s length and diameter, as well as the resistive material, determine the potentiometer’s resistance value. The wiper, made from a conductive material, slides along the resistive wire and makes electrical contact with it. The wiper’s position is adjusted by a shaft, which is connected to an external knob or lever. Finally, the terminal consists of three electrical contacts: one at each end of the resistive wire, and one connected to the wiper.

Working Principle

The wire-wound potentiometer operates on the principle of voltage division. When a voltage is applied across the entire length of the resistive wire, a voltage gradient is established, with the voltage varying linearly or logarithmically along the wire’s length. By adjusting the wiper’s position, a user can tap off a specific fraction of the applied voltage. This output voltage is directly proportional to the wiper’s position along the resistive wire.

In a potentiometer’s three-terminal configuration, the input voltage is applied across the two terminals connected to the resistive wire, and the output voltage is measured between the wiper terminal and one of the resistive wire terminals. In a two-terminal configuration, one of the resistive wire terminals is left unconnected, and the potentiometer acts as a variable resistor, with its resistance value determined by the wiper’s position.

Advantages

Wire-wound potentiometers offer several advantages over other types of potentiometers, such as carbon composition and conductive plastic. Some of these benefits include:

- High precision: The wire-wound construction allows for tight tolerance and accurate resistance values, making these potentiometers suitable for applications requiring precise control.

- High power handling: Due to their wire-wound construction, these potentiometers can dissipate heat more effectively than other types, allowing them to handle higher power levels without significant degradation in performance.

- Long life: The robust construction and materials used in wire-wound potentiometers contribute to their long operational life, making them a reliable choice for various applications.

Limitations

Despite their advantages, wire-wound potentiometers also have some limitations:

- Noise: Due to the mechanical nature of the wiper’s contact with the resistive wire, wire-wound potentiometers can generate noise as the wiper moves along the wire, particularly in audio applications. This noise can be minimized through proper design and the use of low-noise materials, but it may still be a concern in some cases.

- Size and weight: Wire-wound potentiometers tend to be larger and heavier than other types of potentiometers, making them less suitable for compact or lightweight applications.

- Cost: The manufacturing process of wire-wound potentiometers is more complex, resulting in higher costs compared to other types of potentiometers.

Applications

Wire-wound potentiometers find applications in various industries and settings, such as:

- Industrial control systems: They are used to control the speed of electric motors, position of servo systems, and other process variables in industrial automation.

- Audio equipment: Despite their noise limitations, wire-wound potentiometers are still used in some high-end audio equipment, such as amplifiers and mixers, due to their precision and long life.

- Test and measurement equipment: The precision of wire-wound potentiometers makes them ideal for use in calibration devices, voltmeters, and other precision test instruments.

- Automotive: Wire-wound potentiometers are used in throttle position sensors, climate control systems, and other automotive applications that require precise control and robust performance.

Conclusion

Wire-wound potentiometers are essential components in many electronic devices and systems. Their high precision, power handling capabilities, and long life make them a reliable choice for a variety of applications. However, their limitations, such as noise generation, size, and cost, must be considered when selecting the appropriate potentiometer for a specific application. By understanding the construction, working principle, advantages, and limitations of wire-wound potentiometers, engineers and designers can effectively utilize these versatile components to achieve optimal performance in their electronic circuits and systems.